Page 349 - MISUMI Thailand Economy Series

P. 349

Format Series Price Ratio Shipping Search Drawing Product Material Table Techinfo Others BD M D GM Format Series Price Ratio Shipping Search Drawing Product Material Table Techinfo Others BD M D GM

Pict

Title

KW

Title

Pict

KW

Date

Name

Date

Name

AK AK

M M

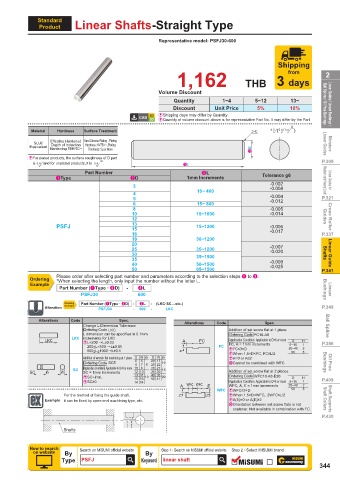

Product Linear Shafts-Straight Type

Linear Shaft Product Overview Standard

Representative model: PSFJ30-600

QAccuracy Standards

· Circularity, Straightness, L Dimension Accuracy · Straightness measurement method Shipping

2 D Shaft ends are supported on V-blocks and 1,162 from 2

turned 360 degrees to measure shaft runout THB 3 days

Linear Guides / Linear Bushings / Ball Splines / Oil Free Bushings · D Section Circularity Medium precision h8 · Straightness Economy Series g7 Medium precision h8 EFor plated products, the surface roughness of D part Unit Price 5~12 10% Ball Splines / Oil Free Bushings Linear Guides / Linear Bushings /

using a dial indicator. 1/2 of measured runout

K

M

-

is defined as the straightness.

Volume Discount

L

Quantity

1~4

13~

Discount

5%

G

is and for unplated products, it is .

0.4

0.4

Shaft Dia. (>) Shaft Dia. (to) Standard product g6 Economy Series g7

Shaft Dia. Overall Length Standard product g6

E Shipping days may differ by Quantity.

-

0.004

0.012

>100

G

0.004

0.012

0.012

13

10 2 5 10 5 0.004 0.012 0.012 3·4 ≤100 (L/100)×0.05 or Less (L/100)×0.05 or Less - Material Hardness Surface Treatment E Quantity of volume discount above is for representative Part No. It may differ by the Part.

6.3

0.4

0.4

2-C

≤100

0.005

(L/100)×0.03 or Less

(L/100)×0.05 or Less

0.016

0.016

18

13

5

Miniature Linear Guides 18 20 0.005 0.016 0.016 6~50 >100 (L/100)×0.01 or Less (L/100)×0.025 or Less (L/100)×0.025 or Less Equivalent Hardening 58HRC~ Thickness: 5µ or More 2D Linear Guides Miniature

Effective Hardened Hard Chrome Plating - Plating

≤100

0.025 or Less

0.025 or Less

0.01 or Less

0.020

0.020

20

SUJ2

40

0.006

Depth of Induction Hardness: HV750 ~, Plating

40

-

0.007

50

>100

0.020

P.309 · L Dimension Tolerances · Perpendicularity EFor plated products, the surface roughness of D part 3L P.309

G

is and for unplated products, it is .

0.4

0.4

Dimension (>) Dimension (to) Standard product g6 Economy Series g7 Medium precision h8

Linear Guides for Medium and Heavy Load 30 2 6 120 ±0.1 D 1Type Part Number 2D 2-C 6.3 0.4 1mm Increments Tolerance g6 Medium and Heavy Load Linear Guides for

3L

6

30

±0.2

G

0.4

-0.002

±0.3

3

400

120

±0.5

±0.8

400

1000

-0.004

P.321 *The medium precision products will be discontinued in July 2024, 0.2 4 5 6 2D 10~ 400 -0.008 P.321

1500

1000

±1.2

-0.012

15~ 800

Cross Roller Guides QSurface Hardness·Surface Treatment Standard 3L 10 15~1000 -0.005 Guides Cross Roller

8

and the economy series can be used for replacement.

-0.014

12

13

-0.017

P.337 · Surface Hardness · Reduced Hardness around Machined Areas PSFJ 15 15~1200 -0.006 P.337

16

30~1200

18

Linear Guide Shafts O.D. (D) Shaft Tolerance g7 (Economy series) Effective hardening layer depth are case hardened. In the example below, annealing caused by machining 20 35~1200 -0.007 Shafts Linear Guide

Surface Treatment Plating Layers Machining is applied after base materials

Effective hardening layer depth of the quenching shaft

25

-0.020

Shaft Tolerance g6

30

may result in reduced hardness of the machined area + 10mm fore and after.

35~1500

SUS440C or equivalent

GB: Equivalent to 45

35

Equivalent to SUJ2 high-hardness corrosion

JIS: Equivalent to S45C

-0.025

65~1500

50

hardness due to annealing are:

P.341 3 4 or More 0.3 or More 0.5 resistant steel The parts that may be reduced in 40 50~1500 -0.009 P.341

or More 0.5

5 About 10 About 10 About 10 · Female thread: when M≥D/2 Ordering Please order after selecting part number and parameters according to the selection steps 1 to 3.

*When selecting the length, only input the number without the letter L.

6~10

Linear Bushings 15~20 or More 0.5 or More 0.7 or More 0.5 · Wrench flat alteration (SC·WSC·SX) Example Part Number (1Type · 2D) - - 3L Bushings Linear

12·13

· Set Screw Flat alteration (FC·WFC)

or More 0.7

600

PSFJ30

or More 0.8

or More 1.0

25~50

→ Same for medium precision products Ordering Part Number (1Type · 2D) - 3L - (LKC·SC…etc.)

P.349 Alteration Example PSFJ30 - 600 - LKC P.349

Ball Spline · Plating of surface treatment D No electroplating treatment is applied to the following parts. Alterations Code Change L Dimension Tolerance Alterations Code Addition of set screw flat at 1 place Ball Spline

Spec.

Spec.

Machining is applied after base materials

are surface treated.

Ordering Code LKC

· Groove part

L dimension can be specified in 0.1mm

Ordering Code FC10-A8

is hard chrome plated.

Application Condition Applicable to D=6 or more

D

EL<200 CL±0.03

P.386 In the example on the right only part D · Female thread part LKC LKC increments for LKC. A FC FC, A = 1mm increments 6~16 H 1 P.386

· Wrench flat, set screw flat, and cut section 200≤L<500 CL±0.05 FC E FC≤3×D 20~40 2

500≤L≤1000CL±0.1 h EWhen 1.5×D<FC, FC≤L/2 50 3

Oil Free Bushings SC Addition of wrench flat machining at 1 place D W L1 8 20 17 10 EA=0 or A≥2 Bushings Oil Free

D W L1

5

6

Ordering Code SC5

XCannot be combined with WFC

8

7

25 22

Application Condition Applicable to D=6 or more 10 8

30 27

15

40 36

13 11

Ordering Code WFC10-A8-E20

ESC+L1≤L

D

15 13

50 41

P.409 SC L1 W SC = 1mm increments 12 10 10 35 30 20 A WFC WFC E Addition of set screw flat at 2 places 20~40 H 1 2 P.409

ESC≥0

Application Condition Applicable to D=6 or more 6~16

16 14

Shaft Supports Shaft Collars Example For the method of fixing the guide shaft, h h WFC EWFC≤3×D 50 3 Shaft Collars Shaft Supports

WFC, A, E = 1mm increments

EWhen 1.5×D<WFC, 2WFC≤L/2

EA(E)=0 or A(E)≥2

it can be fixed by open-end machining type, etc.

X Orientation between set screw flats is not

P.430 coplanar. Not available in combination with FC. P.430

Shafts

Shafts

How to search Search on MISUMI official website Step 1 Search on MISUMI official website Step 2 Select MISUMI brand

on website By By

Type PSFJ Keyword linear shaft

344

110310559529

1BSU @&/ JOEC

1BSU @&/ JOEC