Page 398 - MISUMI Thailand Economy Series

P. 398

Format Series Price Ratio Shipping Search Drawing Product Material Table Techinfo Others BD M D GM Format Series Price Ratio Shipping Search Drawing Product Material Table Techinfo Others BD M D GM

KW

Pict

Pict

Title

KW

Title

Date

Date

Name

Name

AK AK

M M

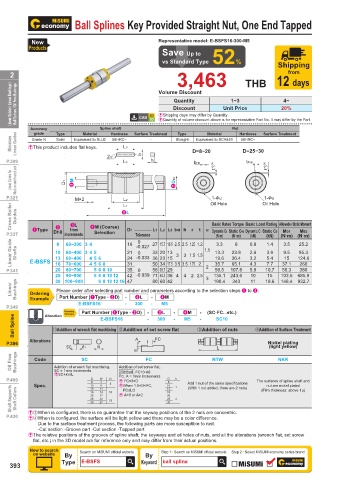

Ball Splines Key Provided Straight Nut, One End Tapped

New Representative model: E-BSFS16-300-M5

Products

Save Up to

vs Standard Type 52% Shipping

from

2 3,463 THB 12 days 2

Linear Guides / Linear Bushings / Ball Splines / Oil Free Bushings Volume Discount Unit Price 20% Ball Splines / Oil Free Bushings Linear Guides / Linear Bushings /

1~3

Quantity

4~

Discount

E Shipping days may differ by Quantity.

E Quantity of volume discount above is for representative Part No. It may differ by the Part.

Accuracy Type Material Spline shaft Surface Treatment Type Material Nut Hardness Surface Treatment

grade

Hardness

Miniature Linear Guides EThis product includes flat keys. 58HRC~ - Straight D=8~20 58HRC~ - Linear Guides Miniature

Solid

Equivalent to SCR420

Grade N

Equivalent to SUJ2

L3

D=25~30

P.309 2-r L3 b h bH8 t +0.05 0 bH8 t +0.05 0 P.309

Linear Guides for Medium and Heavy Load D1 4M 2Dh8 Medium and Heavy Load Linear Guides for

1- φ u

1- φ u

P.321 M×2 L2 Oil Hole Oil Hole P.321

Cross Roller Guides 3L 3L Basic Rated Torque Basic Load Rating Allowable Static Moment Guides Cross Roller

L1

2

1mm

Selection

P.337 1Type Dh8 increments 4M (Coarse) D1 Tolerance L1 L2 L3 bH8 h r t u Dynamic Ct Static C0t Dynamic C Static C0 M01 M02 P.337

(N·m)

(N·m)

(N·m) (N·m)

(kN)

(kN)

Linear Guide Shafts E-BSFS 10 60~300 3 4 4 5 6 16 -0.027 27 15.7 10.5 2.5 2.5 1.25 1.2 1.5 13.3 23.8 0.8 1.4 3.5 124.6 Shafts Linear Guide

0

25.2

6

3.3

8

21

33 20 13

2.6

60~400 3 4 5

3.9

85.3

9.5

0

3

3 1.5 1.5

13

60~400

3.2

36.4

19.6

24

-0.033 36 23 15

15

5.4

65.1

7.7

5 6 8 10

56 39.7 29

380

80~700

59.5

55.3

20

5.9

35

P.341 16 70~600 4 5 6 8 31 0 50 34 17.5 3.5 3.5 1.75 2 2 35.7 107.8 4.3 10.7 37.1 260 P.341

25 90~900 5 6 8 10 12 42 -0.039 71 50.3 36 4 4 2 2.5 3 135.1 243.6 10 19.6 103.5 685.9

15

932.7

190.4

11

30 100~900

343

6 8 10 12 16 47

80 60 42

148.4

Linear Bushings Ordering Please order after selecting part number and parameters according to the selection steps 1 to 4. Bushings Linear

Part Number (1Type · 2D)

Example

E-BSFS16 - - 3L - - 4M

M5

300

P.349 P.349

Ordering Part Number (1Type · 2D) - 3L - 4M - (SC·FC...etc.)

Example

Alteration

Ball Spline 1Addition of wrench flat machining 2Addition of set screw flat M5 3Addition of nuts 4Addition of Surface Treatment Ball Spline

-

SC10

300

-

E-BSFS16

-

P.386 Alterations A FC Nickel plating P.386

SC L1 W L (light yellow)

h

Oil Free Bushings Code Addition of wrench flat machining. Addition of set screw flat. NTW NKR Bushings Oil Free

SC

FC

SC = 1mm increments

Method FC10-A8

ESC+l1≤L FC, A = 1mm increments

P.409 Spec. 10 D 8 W 7 8 l1 8 E FC≤3×D 10 D 8 h 1 Add 1 nut of the same specifications The surfaces of spline shaft and P.409

Shaft Supports Shaft Collars 13 11 10 E A=0 or A≥2 13 2 (Film thickness: above 1μ) Shaft Collars Shaft Supports

E When 1.5×D<FC,

nut are nickel plated

(With 1 nut added, there are 2 nuts)

FC≤L/2

16

14

16

20

17

20

25

25

22

15

30

30

27

P.430 E 3When is configured, there is no guarantee that the keyway positions of the 2 nuts are concentric. P.430

E4 When is configured, the surface will be light yellow and there may be a color difference.

Due to the surface treatment process, the following parts are more susceptible to rust.

-Cut section -Groove part -Cut section -Tapped part

E The relative positions of the grooves of spline shaft, the keyways and oil holes of nuts, and all the alterations (wrench flat, set screw

flat, etc.) in the 3D model are for reference only and may differ from their actual positions.

How to search Search on MISUMI official website Step 1 Search on MISUMI official website Step 2 Select MISUMI economy series brand

on website By By

393 Type E-BSFS Keyword ball spline

110310632969

1BSU @&/ JOEC

1BSU @&/ JOEC