Page 652 - MISUMI Thailand Economy Series

P. 652

7 Economy Series Product Overview Product Overview Economy Series 7

Bearings With Housings Economy series Bearings vs Standard Type QFeatures of MISUMI Economy series Bearings Bearings With Housings Bearings /

Bearings

Bearings

Bearings /

Saving

1Why are all MISUMI Economy series bearings tested for noise and vibration? And why do we insist on achieving "Z1" level?

up to

Bearings Applications of Economy series Bearings 85 % Through the test of bearing noise and vibration, we can find out whether the bearing is defective. Bearing Bearings

vibration is divided into four levels: Z0, Z1, Z2, Z3 and Z4 (Higher level, Lower noise and vibration)

Noise and vibration specifications Noise and Vibration Specifications

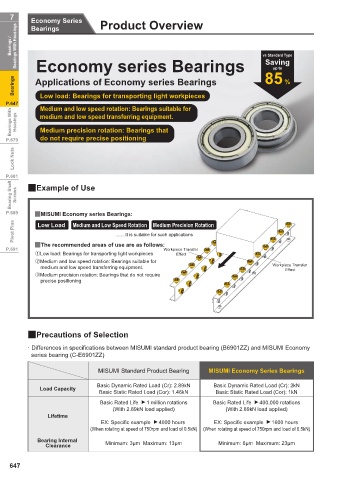

P.647 Low load: Bearings for transporting light workpieces Dimension Tolerance of of generic products on the market * of MISUMI Economy Series P.647

I.D. and O.D., etc.

Medium and low speed rotation: Bearings suitable for

Bearings With Housings medium and low speed transferring equipment. Clearance Tolerance Can Housings Bearings With

Medium precision rotation: Bearings that

guarantee

guarantee

P.679 do not require precise positioning Roundness of Bearing Ball Cannot Z1 P.679

level or

Rail Accuracy of Bearing Inner Z1 level higher

Ring and Outer Ring

Lock Nuts Scratches inside the bearing, Lock Nuts

and foreign matters mixed in

P.681 P.681

Bearing Shaft Screws QExample of Use 2Why do we insist on using "standard wall thickness" for MISUMI Economy series bearings? Screws Bearing Shaft

P.689 QMISUMI Economy series Bearings: Wall thickness of generic products on the market Standard Wall Thickness for MISUMI Economy Series P.689

Pivot Pins Low Load Medium and Low Speed Rotation Medium Precision Rotation Steel Ball The ballistic Steel Ball Deep Rail The ballistic Pivot Pins

……It is suitable for such applications

contact surface is

contact area is

P.691 QThe recommended areas of use are as follows: Workpiece Transfer Shallow Rail reduced and the large, and the P.691

contact stress is

contact stress is

1Low load: Bearings for transporting light workpieces Effect relatively relatively

2Medium and low speed rotation: Bearings suitable for Thinner Wall Thickness concentrated, Standard Wall Thickness dispersed, thus

medium and low speed transferring equipment. Workpiece Transfer thus affecting the prolonging the

Effect

3Medium precision rotation: Bearings that do not require Bearing service life. Bearing service life.

precise positioning Inner Ring Inner Ring

3Why do we insist on using "bearing steel" and "stainless steel" materials with excellent

performance for MISUMI Economy series bearings?

Material and difference for generic Material and difference for

QPrecautions of Selection products on the market * MISUMI Economy series

· Differences in specifications between MISUMI standard product bearing (B6901ZZ) and MISUMI Economy Normal steel on the market SUJ2 (Bearing Steel)

series bearing (C-E6901ZZ) Heat Treatment Hardness Heat Treatment Hardness

48~54HRC Not abrasion 58~63HRC More abrasion

resistant resistant

MISUMI Standard Product Bearing MISUMI Economy Series Bearings Bearing Steel Product

QResult After Test QResult After Test

After service life test under After the long-term service life

Basic Dynamic Rated Load (Cr): 2.89kN Basic Dynamic Rated Load (Cr): 2kN

Load Capacity the same conditions as test, there was little wear inside

Basic Static Rated Load (Cor): 1.46kN Basic Static Rated Load (Cor): 1kN MISUMI Economy series, the open end cover was the open end cover and the structure remains intact.

Basic Rated Life 1 million rotations Basic Rated Life ▲ 400,000 rotations severely worn inside and the structure was damaged.

▲

(With 2.89kN load applied) (With 2.89kN load applied)

Lifetime Normal stainless steel on the Equivalent to SUS440 or SUS420

EX: Specific example ▲ 4000 hours EX: Specific example ▲ 1600 hours Stainless Steel Product market After the salt spray After the salt spray test, the rusted

(When rotating at speed of 750rpm and load of 0.5kN) (When rotating at speed of 750rpm and load of 0.5kN) test, the rusted area was area was about 2~3%

about 30%

Bearing Internal

Clearance Minimum: 3μm Maximum: 13μm Minimum: 6μm Maximum: 23μm * Generic products on the market are similar products randomly purchased by our company from online or offline markets

* The test data are obtained through testing by our company, which are for reference only

647