Page 71 - MISUMI Thailand Economy Series

P. 71

Format Series Price Ratio Shipping Search Drawing Product Material Table Techinfo Others BD M D GM Format Series Price Ratio Shipping Search Drawing Product Material Table Techinfo Others BD M D GM

Title

Pict

KW

Title

KW

Pict

Date

Name

Date

Name

AK AK

M M

1 1

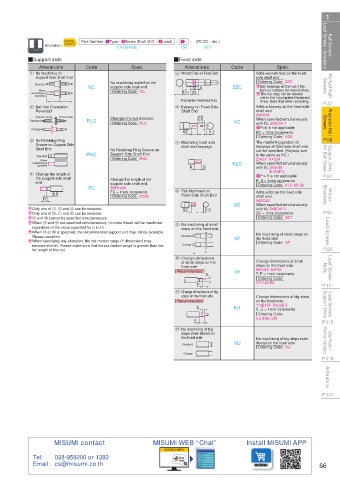

Ball Screws / Lead Screws / Actuators QSupport side Ordering Part Number (1Type · 2Screw Shaft O.D. · 3Lead) QFixed side SC7 Lead Screws / Actuators Ball Screws /

(FC·SC…etc.)

- 4L -

Example

Alteration

C-KBS1002

- 150 -

Alterations

Spec.

Spec.

Alterations

No Machining on

Rolled Ball Screws 1 machining is Code No machining added on the 5 Wrench Flats on Fixed Side Code Adds wrench flats on the fixed Screws Rolled Ball

side shaft end.

Support Side Shaft End

Ordering Code SZC

Standard

SZC

E Ball bearings will fall out if the

NC

support side shaft end.

5

5

ball nut crosses the wrench flats.

0

When

Ordering Code NC

30

8-0.2

E The nut may not be moved

Area. Note that when selecting.

P.37 specified L Incomplete Hardened Area within the Incomplete Hardened P.37

2 Ball Nut Orientation 6 Keyway on Fixed Side Adds a keyway on the fixed side

Precision Ball Screws Standard (Fixed side) RLC Changes the nut direction. -0.004 -0.029 2 KC 2≤KC≤8 Screws Precision Ball

Shaft End

shaft end.

Reversed

(Support side)

When specified simultaneously

with 0, 2≤KC≤F-1

Ordering Code RLC

XP=5 is not applicable

Change

KC

1.2

Ordering Code KC5

P.59 3 No Retaining Ring 7 Machining fixed side KC = 1mm increments P.59

The machining position of

Groove on Support Side

Support Units for Ball Screw machining is RNC No Retaining Ring Groove on K S KLC can be specified. (Keyway size for Ball Screw Support Units

shaft end keyways

keyways at fixed side shaft end

Shaft End

Support Side Shaft End

is the same as KC.)

Standard

2≤K≤7 K+S≤8

Ordering Code RNC

When

When specified simultaneously

specified

K+S≤F-1

P.81 4 Change the length of Change the length of the with 0, 2≤K≤16 P.81

XP = 5 is not applicable

the support side shaft

end FC support side shaft end. K, S = 1mm increments

Ordering Code KLC-K5-S2

9≤FC≤20

Motor Brackets FC 6.8 FC = 1mm increments 8 Flat Machined on Adds a flat on the fixed side Brackets Motor

Fixed Side Shaft End

shaft end.

Ordering Code FC20

5≤SC≤8

E Only one of 1, 3 and 4 can be selected. SC 0.5 SC When specified simultaneously

with 0, 5≤SC≤F-1

P.91 E Only one of 6, 7 and 8 can be selected. SC = 1mm increments P.91

Ordering Code SC7

E 9 and 0 cannot be specified simultaneously.

Lead Screws E When Q and W are specified simultaneously, no male thread will be machined 9 No machining of small NF No machining of small steps on Lead Screws

regardless of the value specified for U in Q.

steps on the fixed side

E When Q or W is specified, the recommended support unit may not be available.

Please reconfirm.

Standard

the fixed side

become shorter. Please make sure that the nut motion range is greater than the

Change

P.93 E When specifying any alteration, the nut motion range (Y dimension) may 0 Change dimensions Ordering Code NF P.93

full length of the nut.

L

Lead Screw Nuts Recommended P FP Change dimensions of small Nuts Lead Screw

of small steps on the

steps on the fixed side

fixed side

9≤F≤18 5≤P≤6

F, P = 1mm increments

Ordering Code

F

P.111 Q Change dimensions of big FP-F18-P6 P.111

Lead Screws Support Units Recommended EU Change dimensions of big steps Support Units Lead Screws

steps on the fixed side

on the fixed side

11≤E≤35 8≤U≤E-3

U

E, U = 1mm increments

Ordering Code

E

P.115 W No machining of big EU-E35-U10 P.115

Stop Plates / Position Indicators steps male thread on NU No machining of big steps male Position Indicators Stop Plates /

the fixed side

thread on the fixed side

Standard

Ordering Code NU

P.119 Change P.119

Actuators Actuators

P.131 P.131

MISUMI contact MISUMI WEB “Chat” Install MISUMI APP

MISUMI WEB

Tel: 038-959200 or 1382

Email: cs@misumi.co.th 66

110310541889

1BSU @&/ JOEC

1BSU @&/ JOEC