Page 751 - MISUMI Thailand Economy Series

P. 751

Format Series Price Ratio Shipping Search Drawing Product Material Table Techinfo Others BD M D GM Format Series Price Ratio Shipping Search Drawing Product Material Table Techinfo Others BD M D GM

KW

Title

Title

KW

Pict

Pict

Date

Name

Name

Date

AK AK

M M

Economy series Product Overview Product Overview Economy series

Locating Pins / Bushings Locating Pins / Bushings

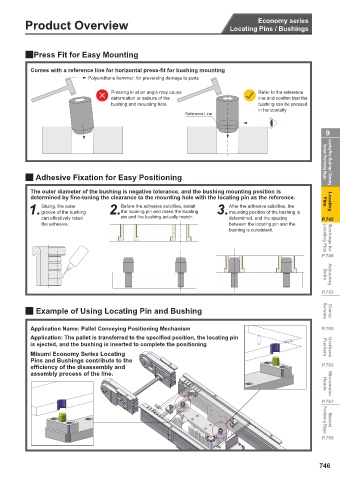

vs Standard Type QPress Fit for Easy Mounting

Economy series Locating Saving Comes with a reference line for horizontal press-fit for bushing mounting

up to

Pins / Bushings 87 % Polyurethane hammer, for preventing damage to parts

Pressing in at an angle may cause

deformation or seizure of the Refer to the reference

line and confirm that the

● Suitable for positioning at bushing and mounting hole. bushing can be pressed

in horizontally

working station in Reference Line

production lines. 9

● Designed for smooth

insertion and removal for

automation Screws / Positioning Stages Locating Pins / Bushings / Clamping

Q Adhesive Fixation for Easy Positioning

QCategories of use The outer diameter of the bushing is negative tolerance, and the bushing mounting position is

determined by fine-tuning the clearance to the mounting hole with the locating pin as the reference.

Tapered / Spherical Locating Pin Press Fit for Easy Mounting Adhesive Fixation for Easy Positioning Pins Locating

1. Gluing, the outer 2. Before the adhesive solidifies, install 3. After the adhesive solidifies, the

the locating pin and make the locating

groove of the bushing

mounting position of the bushing is

can effectively retain pin and the bushing actually match. determined, and the spacing P.745

Recommended Applications

the adhesive. between the locating pin and the

bushing is consistent. Locating Pins Bushings for

· Priority in positioning accuracy, Positioning Side I.D. Tolerance

MISUMI small pin sleeve fit clearance O.D. Tolerance

standard · Fixtures with manual disassembly G6 +0.01 — P.749

product and assembly and less 0 0

disassembly times -0.01 * Two I.D. tolerance specifications Bolts Adjusting

· Priority in smooth disassembly and Positioning Side

MISUMI assembly, large pin sleeve fit clearance O.D. Tolerance I.D. Tolerance

Economy · Workstations on automatic -0.01 O.D. Negative Tolerance P.753

series production lines with frequent -0.02 F7

disassembly and assembly

Q Example of Using Locating Pin and Bushing Screws Clamp

QMISUMI Economy series products respond to the voice of customers and on-site problems are improved

Application Name: Pallet Conveying Positioning Mechanism P.760

Pin / Bushing Fitting Clearance Pin / Bushing Mounting Hole Pitch Application: The pallet is transferred to the specified position, the locating pin

Bushing Mounting Hole Pitch is ejected, and the bushing is inserted to complete the positioning

Voice of Customer Voice of Customer Pushers Urethane

Locating Pin: JPBB6-8 Clearance between Pins and Bushings are Pins and Busings require the same pitch between Misumi Economy Series Locating

too tight, and the plugging and unplugging

the mounting holes of the two plates, and the

Bushing: JBHM8-12 on the automatic production line is not press-in installation requires high accuracy of the Pins and Bushings contribute to the

MISUMI smooth, which easily leads to downtime. hole pitch, which makes processing difficult. efficiency of the disassembly and P.763

standard assembly process of the line.

product Fit Clearance

0.004~0.022 Heads Micrometer

Locating Pin Mounting Hole Pitch

Economy series Locating Pins, Bushings Adhesive Fixation for Easy Positioning P.767

Locating Pin: P.747 Fit Used in conjunction, narrowing Position Adjusting Clearance Fine-tuning the mounting

Clearance

MISUMI Bushing: P.750 the gap, facilitating the position of the bushing, with

disassembly and assembly on

Economy the production line the locating pin actual Positioning Stages Motorized

series Fit Clearance Locating Pin: Mounting Side O.D. D 6mm, matching, to relieve the

pressure of the mounting hole

Positioning Side O.D. P 8mm

0.023~0.048 Bushing: I.D. Dimension d 8mm, Pin Sleeve Mounting Hole Pitch machining accuracy P.769

Length L 12mm

746

1BSU @&/ JOEC

1BSU @&/ JOEC