Page 764 - MISUMI Thailand Economy Series

P. 764

Format Series Price Ratio Shipping Search Drawing Product Material Table Techinfo Others BD M D GM Format Series Price Ratio Shipping Search Drawing Product Material Table Techinfo Others BD M D GM

Title

KW

KW

Pict

Title

Pict

Date

Name

Name

Date

AK AK

M M

Economy series

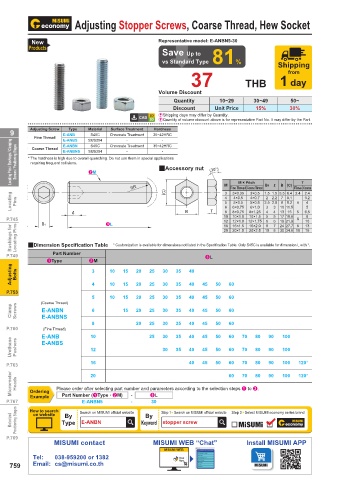

Adjusting Stopper Screws, Coarse Thread, Hew Socket Product Overview Clamping Screws

New Representative model: E-ANBN5-30

Products

Save Up to vs Standard Type

vs Standard Type 81% Shipping Economy series Saving

37 THB 1 day up to

from

Volume Discount Clamping Screws 72 %

Quantity 10~29 30~49 50~

Discount Unit Price 15% 30% Thread Strength 12.9

E Shipping days may differ by Quantity.

E Quantity of volume discount above is for representative Part No. It may differ by the Part.

Free Rotation of Ball

Type

Hardness

Surface Treatment

9 Adjusting Screw E-ANB Material Chromate Treatment 35~42HRC

S45C

Fine Thread

E-ANBS

Locating Pins / Bushings / Clamping Screws / Positioning Stages * The hardness is high due to overall quenching. Do not use them in special applications (30°)

-

-

SUS304

S45C

35~42HRC

E-ANBN

Chromate Treatment

Coarse Thread

SUS304

-

-

E-ANBNS

requiring frequent collisions.

QAccessory nut

2M

M × Pitch

B (C)

B1 R

SR (C) M 3 Fine Thread Coarse Thread 1.5 1.5 5.5 6.4 2.4 T 2.4 QAdvantages of Clamp Screw

Fine Coarse

Locating Pins 4 5 6 6×0.75 4×0.7 2.5 2.8 10 11.5 4 3.2 · Problems with using conventional set screws · Ease of using clamp screws

3×0.35

3×0.5

2.2

2

8.1

7

4×0.5

4

8

9.2

5×0.8

5×0.5

6×1.0

3

3

5

l B T 8 8×0.75 8×1.25 4 4 13 15 5 6.5 Hexagon Socket Set Screw Clamp Screws

10

10×1.5

P.745 B1 3L 16 10×1.0 12×1.75 5 6 8 5 6 7 17 19.6 6 10 8 The head of the set screw The ball of the clamp

12

19 21.9

screw makes point contact

12×1.0

16×1.5

16×2.0

Bushings for Locating Pins QDimension Specification Table * Customization is available for dimensions not listed in the Specification Table. Only S45C is available for dimension L with *. Burnt is uneven, which is easy is a good solution to the

24 27.7 8

13

with the workpiece, which

30 34.6 10

16

8

20×2.5

10

20

20×1.5

problem of pinch damage.

to pinch the workpiece.

The front-end ball can

completely loosened to

P.749 Part Number 3L Workpiece The set screw has to be adjust the workpiece

under micro preloading,

1Type 2M adjust the position, which ensuring the accuracy

Adjusting Bolts 3 10 15 20 25 30 35 40 QDifference Between Clamp Screws and Plungers Adjusting Position and easy adjustment.

is very inconvenient.

P.753 4 10 15 20 25 30 35 40 45 50 60 · Plunger principle: with a built-in spring, the front end ball will · Clamp screw principle: the workpiece is fixed by

5 10 15 20 25 30 35 40 45 50 60

(Coarse Thread) sink into the main body after bearing the load, and recover the screw thrust and the point contact of the ball.

Clamp Screws E-ANBN 6 15 20 25 30 35 40 45 50 60 under the action of the spring after releasing the load. Clamp Screws

E-ANBNS

8 20 25 30 35 40 45 50 60 Temporary Workpiece

P.760 E-ANB 10 25 30 35 40 45 50 60 70 80 90 100 Positioning Clamping

(Fine Thread)

and Angle

Function

Urethane Pushers E-ANBS 12 30 35 40 45 50 60 70 80 90 100 Adjustment

QExample of Using Clamp Screw

P.763 16 40 45 50 60 70 80 90 100 120* · Ball type and angle plate combination: the

Micrometer Heads Ordering Please order after selecting part number and parameters according to the selection steps 1 to 3. 90 100 120* ball can be rolled for easy adjustment. Angle Plate Type

70

60

20

80

Example

30

E-ANBN5

P.767 How to search Part Number (1Type · 2M) - - 3L Ball Type

By

By

Motorized Positioning Stages on website Type Search on MISUMI official website Keyword Step 1 Search on MISUMI official website Step 2 Select MISUMI economy series brand · Angle plate type (flat head) adjusts the height and angle of the workpiece. Fixture

stopper screw

E-ANBN

Workpiece

18°

P.769

MISUMI contact MISUMI WEB “Chat” Install MISUMI APP Clamp Screws

MISUMI WEB 1 Screw Height Adjustment 2 Fixing Nut 3 Workpiece Swing 4 Workpiece Flattening

Tel: 038-959200 or 1382

759 Email: cs@misumi.co.th

110310684719_110310684989

1BSU @&/ JOEC

1BSU @&/ JOEC