Page 111 - MISUMI Thailand Economy Series

P. 111

Format Series Price Ratio Shipping Search Drawing Product Material Table Techinfo Others BD M D GM Format Series Price Ratio Shipping Search Drawing Product Material Table Techinfo Others BD M D GM

Pict

Title

KW

Pict

KW

Title

Date

Name

Name

Date

AK AK

M M

1 1

Ball Screws / Lead Screws / Actuators Alteration Ordering Part Number (1Type · 2D) - 3L - 4S - 5Q - 6C - 7J - (MC·MQ…etc.) Lead Screws / Actuators Ball Screws /

Example

- 400 - S20 - Q12 - C10 - J5 -

MC8

C-MTSRB16

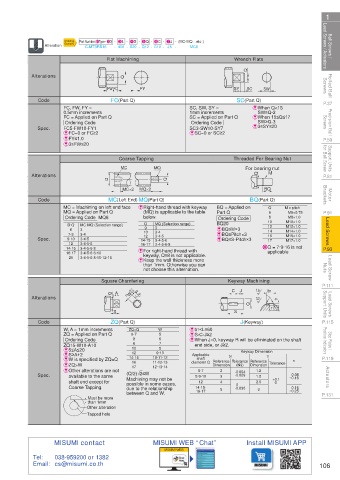

Flat Machining

Wrench Flats

Q

Rolled Ball Screws FW FC FY SY SC SW Screws Rolled Ball

Alterations

Q

P.37 Code FC, FW, FY = FC(Part Q) SC, SW, SY = SC(Part Q) P.37

E When Q<15

Precision Ball Screws Spec. FC = Applied on Part Q SC = Applied on Part Q E When 15≤Q≤17 Screws Precision Ball

SW≥Q-2

1mm increments

0.5mm increments

SW≥Q-3

Ordering Code

Ordering Code

E3≤SY≤20

FC5-FW10-FY1

SC3-SW10-SY7

EFY≤1.0

P.59 EFC=0 or FC≥2 ESC=0 or SC≥2 P.59

E3≤FW≤20

Support Units for Ball Screw Coarse Tapping Threaded For Bearing Nut for Ball Screw Support Units

M

Q

P.81 Alterations MC MQ For bearing nut P.81

D Q

BQ

MQ×2

MC×2

Motor Brackets Code MC(Left End) MQ(Part Q) BQ(Part Q) Brackets Motor

MC = Machining on left end face E Right-hand thread with keyway BQ = Applied on Q M x pitch

P.91 MQ = Applied on Part Q (MQ) is applicable to the table Part Q 10 M10×1.0 P.91

6

M6×0.75

below.

Ordering Code MQ6

M8×1.0

8

Ordering Code

Lead Screws Spec. D·Q MC·MQ (Selection range) 14·15 MQ (Selection range) BQ20 12 M12×1.0 Lead Screws

Q

9

EBQ≤M×3

3

6

3

14

M14×1.0

3·4

10

EBQ≥Pitch×3

7·8

3·4

15

M15×1.0

12

3·4·5

3·4·5

9·10

EBQ≤S-Pitch×3

3·4·5·6

M17×1.0

17

12

16·17

3·4·5·6·8

P.93 14·15 3·4·5·6 E For right-hand thread with X Q = 7·9·16 is not P.93

3·4·5·6·8

16·17 3·4·5·6·8·10 E Keep the wall thickness more applicable

keyway, Q≤8 is not applicable.

Lead Screw Nuts than 1mm. Otherwise you can Nuts Lead Screw

25

3·4·5·6·8·10·12·16

not choose this alternation.

P.111 Square Chamfering Keyway Machining b1 P.111

1.6

-0.1

C

J

-0.3

Lead Screws Support Units Alterations S S Q 3.2 r1 t1 Support Units Lead Screws

A

W

Q

3.2

P.115 Code W, A = 1mm increments ZQ(Part Q) W Eb1<L≤60 J(Keyway) P.115

ZQ=Q

Stop Plates / Position Indicators ZQ = Applied on Part Q 6·7 5 6 7 8 ES-C-J≥2 Position Indicators Stop Plates /

8

E When J=0, keyway R will be eliminated on the shaft

Ordering Code

9

end side, or J≥2.

ZQ15-W10-A10

10

Keyway Dimension

12

9·10

ES≥A+2

Applicable

b1

P.119 E5≤A≤20 14·15 10·11·12 diameter Q Reference Tolerance Reference t1 r1 P.119

shaft

EW is specified by ZQ=Q

11·12·13

16

EZQ>W 17 12·13·14 6·7 Dimension (N9) Dimension Tolerance

Actuators Spec. available to the same (Q/2)√2≤W 8·9·10 3 4 -0.004 1.8 +0.1 ~0.16 Actuators

E Other alterations are not

2

1.2

0.08

-0.029

Machining may not be

shaft end except for

2.5

12

0

possible in some cases,

0

0.16

16·17

between Q and W.

P.131 Coarse Tapping. due to the relationship 14·15· 5 -0.030 3 ~0.25 P.131

Must be more

than 1mm

Other alteration

Tapped hole

MISUMI contact MISUMI WEB “Chat” Install MISUMI APP

MISUMI WEB

Tel: 038-959200 or 1382

Email: cs@misumi.co.th 106

110310581759

1BSU @&/ JOEC

1BSU @&/ JOEC