Page 231 - MISUMI Thailand Economy Series

P. 231

Format Series Price Ratio Shipping Search Drawing Product Material Table Techinfo Others BD M D GM Format Series Price Ratio Shipping Search Drawing Product Material Table Techinfo Others BD M D GM

Title

KW

Title

Pict

KW

Pict

Name

Name

Date

Date

AK AK

M M

1 1

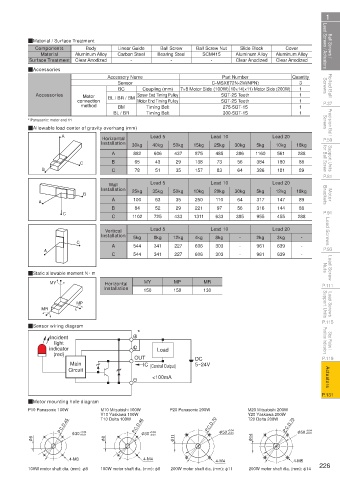

Ball Screws / Lead Screws / Actuators QMaterial / Surface Treatment Carbon Steel Bearing Steel Ball Screw Nut Aluminum Alloy Aluminum Alloy Lead Screws / Actuators Ball Screws /

Slide Block

Components

Ball Screw

Cover

Linear Guide

Body

Aluminum Alloy

Material

SCM415

-

Clear Anodized

Surface Treatment

-

Clear Anodized

-

Clear Anodized

Rolled Ball Screws QAccessories Accessory Name Coupling (mm) 7×8 Motor Side (100W) 10×14(×11) Motor Side (200W) Quantity Screws Rolled Ball

Part Number

Sensor

C-MSX672N-2M(NPN)

3

BC

1

Motor

Motor End Timing Pulley

5GT-25 Teeth

P.37 Accessories connection BL / BR / BM Screw End Timing Pulley 5GT-25 Teeth 1 1 1 1 P.37

method

BM

275-5GT-15

Timing Belt

Precision Ball Screws * Panasonic: motor end 11 Screws Precision Ball

Timing Belt

BL / BR

300-5GT-15

QAllowable load center of gravity overhang (mm)

Horizontal

P.59 A Installation 30kg Lead 5 50kg 15kg Lead 10 30kg 5kg Lead 20 18kg P.59

10kg

25kg

40kg

Support Units for Ball Screw C B 882 606 437 875 485 386 1160 561 288 for Ball Screw Support Units

A

384

180

56

43

29

88

138

65

73

P.81 B C 78 51 35 157 83 64 386 181 89 P.81

Wall Lead 5 Lead 10 Lead 20

Installation

Motor Brackets B A 25kg 35kg 50kg 10kg 20kg 30kg 5kg 12kg 18kg Brackets Motor

250

110

35

63

89

317

100

147

64

A

B 84 52 29 221 97 56 316 144 88

P.91 C C 1102 725 433 1311 633 385 955 455 288 P.91

Lead Screws Installation 5kg Lead 5 12kg 4kg Lead 10 - 2kg Lead 20 - Lead Screws

Vertical

8kg

8kg

3kg

A

P.93 A C C 544 341 227 606 303 - - 961 639 - - P.93

961

227

606

303

544

639

341

Lead Screw Nuts QStatic allowable moment N · m Nuts Lead Screw

MY

MP

Horizontal

P.111 MY Installation 150 150 MR P.111

130

Lead Screws Support Units Mechanical limit of Origin of slide block Effective Stroke 134 Mechanical limit of MR MP Support Units Lead Screws

L

133

slide block

slide block

45±1

P.115 38±1 102 4-M5 Depth 15 φ 10 Pneumatic joint QSensor wiring diagram P.115

Stop Plates / Position Indicators 64 2- φ 5 H7 Depth 12 23 indicator * Position Indicators Stop Plates /

Incident

light

80

Two holes at the same position on the opposite side

50

P.119 7 170 4-M4 Depth 10 92 (red) OUT Load DC P.119

Main IC (Control Output) 5~24V

Actuators 82.5 64 <100mA Actuators

Circuit

50 Effective Stroke + 25 5H7 Depth 7

P.131 102 P.131

85

102 85 1 108 QMotor mounting hole diagram

P10 Panasonic 100W M10 Mitsubishi 100W P20 Panasonic 200W M20 Mitsubishi 200W

φ5 H7 Effective Stroke 7 N-M5 Depth 9 Y10 Yaskawa 100W Y20 Yaskawa 200W

P.C.D.45 P.C.D.46 P.C.D.70 +0.04 P.C.D.70 +0.04

84 M*200 A 83 T10 Delta 100W T20 Delta 200W

+0.01

+0.01

φ 8 φ 30 +0.04 φ 8 φ 30 +0.04 φ 11 φ 50 +0.01 φ 14 φ 50 +0.01

4-M3 4-M4 4-M4 4-M5

100W motor shaft dia. (mm): φ8 100W motor shaft dia. (mm): φ8 200W motor shaft dia. (mm): φ11 200W motor shaft dia. (mm): φ14 226

110310667169

1BSU @&/ JOEC

1BSU @&/ JOEC