Page 303 - MISUMI Thailand Economy Series

P. 303

Format Series Price Ratio Shipping Search Drawing Product Material Table Techinfo Others BD M D GM Format Series Price Ratio Shipping Search Drawing Product Material Table Techinfo Others BD M D GM

Pict

Title

KW

KW

Title

Pict

Name

Date

Name

Date

AK AK

M M

1 1

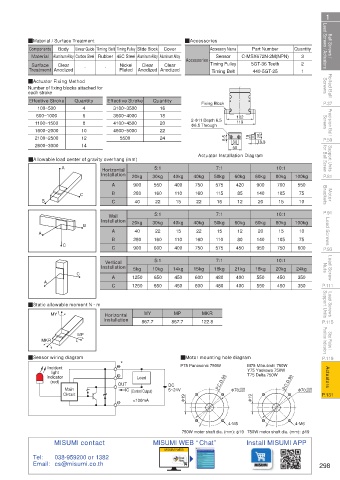

Ball Screws / Lead Screws / Actuators QMaterial / Surface Treatment Cover QAccessories Sensor C-MSX672N-2M(NPN) Quantity Lead Screws / Actuators Ball Screws /

Part Number

Linear Guide Timing Belt Timing Pulley Slide Block

Body

Accessory Name

Components

3

Material Aluminum Alloy Carbon Steel Rubber 45C Steel Aluminum Alloy Aluminum Alloy

Surface

Clear

Clear

Nickel

Clear

Treatment Anodized - - Plated Anodized Anodized Accessories Timing Pulley 5GT-36 Teeth 2 1

440-5GT-25

Timing Belt

Rolled Ball Screws QActuator Fixing Method Screws Rolled Ball

Number of fixing blocks attached for

each stroke

P.37 Effective Stroke Quantity Effective Stroke Quantity Fixing Block P.37

3100~3500

100~500

4

16

Precision Ball Screws 1100~1500 10 3600~4000 18 φ 6.5 Through 102 Screws Precision Ball

600~1000

6

2- φ 11 Depth 6.5

119

8

4100~4500

20

22

4600~5000

1600~2000

25

P.59 2100~2500 12 5500 24 8.5 30 19 15.5 P.59

14

2600~3000

Support Units for Ball Screw QAllowable load center of gravity overhang (mm) Actuator Installation Diagram for Ball Screw Support Units

50

10:1

7:1

5:1

Horizontal

P.81 A Installation 20kg 30kg 40kg 40kg 50kg 60kg 60kg 80kg 100kg P.81

A 900 550 400 750 575 420 900 700 550

Motor Brackets B C B 280 160 110 160 115 85 140 105 75 Brackets Motor

10

12

40

22

16

15

15

22

20

C

P.91 Installation 5:1 7:1 10:1 P.91

Wall

Lead Screws A B B 20kg 30kg 40kg 40kg 50kg 60kg 60kg 80kg 100kg Lead Screws

22

A

15

15

10

20

15

12

22

40

280

80

110

75

160

110

105

140

160

P.93 C C 900 600 400 750 575 450 950 750 600 P.93

Lead Screw Nuts C Installation 5kg 10kg 14kg 15kg 18kg 21kg 18kg 20kg 24kg Nuts Lead Screw

7:1

10:1

5:1

Vertical

A

550

350

400

450

480

450

1250

P.111 A C 1250 650 450 600 480 400 550 450 350 P.111

650

600

Lead Screws Support Units QStatic allowable moment N · m Support Units Lead Screws

MY

MP

Horizontal

122.8

P.115 MY Installation 867.7 867.7 MKR P.115

Stop Plates / Position Indicators MKR MP Position Indicators Stop Plates /

P.119 QSensor wiring diagram QMotor mounting hole diagram P.119

* P75 Panasonic 750W M75 Mitsubishi 750W

Incident

Actuators indicator Load P.C.D.90 Y75 Yaskawa 750W P.C.D.90 Actuators

light

T75 Delta 750W

(red)

Main OUT IC (Control Output) DC φ 70 +0.01 φ 70 +0.01

5~24V

+0.04

+0.04

P.131 Circuit P.131

<100mA φ 19 φ 19

4-M5 4-M6

750W motor shaft dia. (mm): φ19 750W motor shaft dia. (mm): φ19

MISUMI contact MISUMI WEB “Chat” Install MISUMI APP

MISUMI WEB

Tel: 038-959200 or 1382

Email: cs@misumi.co.th 298

110310673379

1BSU @&/ JOEC

1BSU @&/ JOEC