Page 299 - MISUMI Thailand Economy Series

P. 299

Format Series Price Ratio Shipping Search Drawing Product Material Table Techinfo Others BD M D GM Format Series Price Ratio Shipping Search Drawing Product Material Table Techinfo Others BD M D GM

KW

Title

KW

Pict

Title

Pict

Name

Name

Date

Date

AK AK

M M

1 1

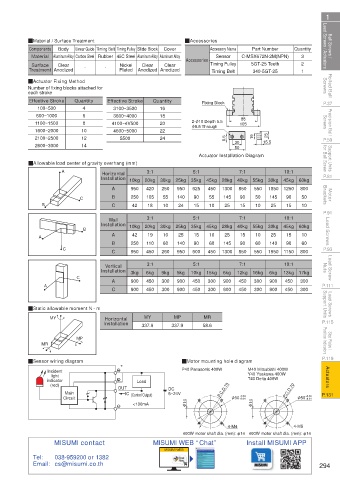

Ball Screws / Lead Screws / Actuators QMaterial / Surface Treatment Cover QAccessories Sensor C-MSX672N-2M(NPN) Quantity Lead Screws / Actuators Ball Screws /

Part Number

Linear Guide Timing Belt Timing Pulley Slide Block

Body

Accessory Name

Components

3

Material Aluminum Alloy Carbon Steel Rubber 45C Steel Aluminum Alloy Aluminum Alloy

Surface

Nickel

Clear

Clear

Clear

Treatment Anodized - - Plated Anodized Anodized Accessories Timing Pulley 5GT-25 Teeth 2 1

Timing Belt

340-5GT-25

Rolled Ball Screws QActuator Fixing Method Screws Rolled Ball

Number of fixing blocks attached for

each stroke

P.37 Effective Stroke Quantity Effective Stroke Quantity Fixing Block P.37

3100~3500

100~500

4

16

Precision Ball Screws 1100~1500 10 4100~4V500 18 φ 5.5 Through 105 Screws Precision Ball

600~1000

6

3600~4000

88

2- φ 10 Depth 5.5

8

20

22

1600~2000

4600~5000

25

P.59 2100~2500 12 5500 24 8.5 30 19 15.5 P.59

14

2600~3000

Support Units for Ball Screw QAllowable load center of gravity overhang (mm) Actuator Installation Diagram for Ball Screw Support Units

50

7:1

3:1

10:1

5:1

Horizontal

P.81 A Installation 10kg 20kg 30kg 25kg 35kg 45kg 28kg 40kg 55kg 30kg 45kg 60kg P.81

A

Motor Brackets C B 950 420 250 950 625 450 1300 850 550 1850 1250 800 Brackets Motor

50

145

105

90

50

90

55

140

145

55

90

250

15

15

18

C

15

P.91 B Wall 42 3:1 10 24 5:1 10 25 7:1 10 25 10:1 10 P.91

Lead Screws A B Installation 10kg 20kg 30kg 25kg 35kg 45kg 28kg 40kg 55kg 30kg 45kg 60kg Lead Screws

10

25

15

15

25

10

10

15

25

42

10

19

A

90

60

60

90

90

140

60

145

60

P.93 C B 250 110 260 140 600 450 1300 850 550 1950 1150 800 P.93

C

450

950

950

Lead Screw Nuts Installation 3kg 6kg 9kg 5kg 10kg 15kg 6kg 12kg 16kg 6kg 13kg 17kg Nuts Lead Screw

10:1

7:1

3:1

5:1

Vertical

A

P.111 A C C 900 450 300 900 450 300 900 450 300 900 450 300 P.111

300

300

300

900

900

450

450

450

900

900

300

450

Lead Screws Support Units QStatic allowable moment N · m Support Units Lead Screws

MP

MR

MY

Horizontal

P.115 MY Installation 337.9 337.9 58.6 P.115

Stop Plates / Position Indicators MR MP Position Indicators Stop Plates /

P.119 P.119

QSensor wiring diagram * QMotor mounting hole diagram

Actuators indicator Load P40 Panasonic 400W M40 Mitsubishi 400W Actuators

Incident

Y40 Yaskawa 400W

light

T40 Delta 400W

(red)

5~24V

P.131 Main OUT IC (Control Output) DC P.C.D.70 +0.04 P.C.D.70 +0.04 P.131

Circuit φ 50+0.01 φ 50+0.01

<100mA φ 14 φ 14

4-M4 4-M5

400W motor shaft dia. (mm): φ14 400W motor shaft dia. (mm): φ14

MISUMI contact MISUMI WEB “Chat” Install MISUMI APP

MISUMI WEB

Tel: 038-959200 or 1382

Email: cs@misumi.co.th 294

110310673469

1BSU @&/ JOEC

1BSU @&/ JOEC