Page 326 - MISUMI Thailand Economy Series

P. 326

Format Series Price Ratio Shipping Search Drawing Product Material Table Techinfo Others BD M D GM Format Series Price Ratio Shipping Search Drawing Product Material Table Techinfo Others BD M D GM

KW

Pict

Title

KW

Title

Pict

Name

Date

Date

Name

AK AK

M M

Economy Series Product Overview Product Overview Economy Series

Linear Guides for Medium and Heavy Load Linear Guides for Medium and Heavy Load

· Running Parallelism ·【Running Parallelism】 The values in the table are all measured after the rail is fixed on the

vs Standard Type reference base.When moving the slider within the full length of the rail, measure the change of the

Economy Series Saving Rail Length (mm) Accuracy grade (μm) block upper surface C relative to the slide rail bottom surface A and the change of the block

up to

2 Linear Guides for 77 % 100~200 14 reference surface D relative to the slide rail reference surface B. 2

15

200~300

· Running parallelism of surface C

· Running parallelism of surface D

Linear Guides / Linear Bushings / Ball Splines / Oil Free Bushings Medium and Heavy Load 1100~1500 20 Ball Splines / Oil Free Bushings Linear Guides / Linear Bushings /

against surface B

against surface A

17

300~500

500~700

700~900

22

900~1100

24

26

1500~1900

28

2500~3100

33

Short delivery time

Miniature Linear Guides Various range of blocks 1900~2500 31 * The above figure shows machining until the surface A (slide rail mounting surface) is flat, Linear Guides Miniature

3100~3600

36

37

3600~3960

and the surface B and the surface E (slide rail contact surface) are parallel.

P.309 Interchangeable blocks QAllowable Load The latest availability of lengths over 2m can be confirmed on web product page. P.309

Linear Guides for Medium and Heavy Load · Basic Dynamic Rated Load (C) 3 Medium and Heavy Load Linear Guides for

The basic dynamic rated load is the load that enables a group of identical linear guides to move separately under the same conditions, 90% of which will

not cause material damage due to rolling fatigue, and will slide 50×10 m in a constant direction.

The basic static rated load is the static load required to make the sum of the permanent deformation amount of the rolling element and the permanent

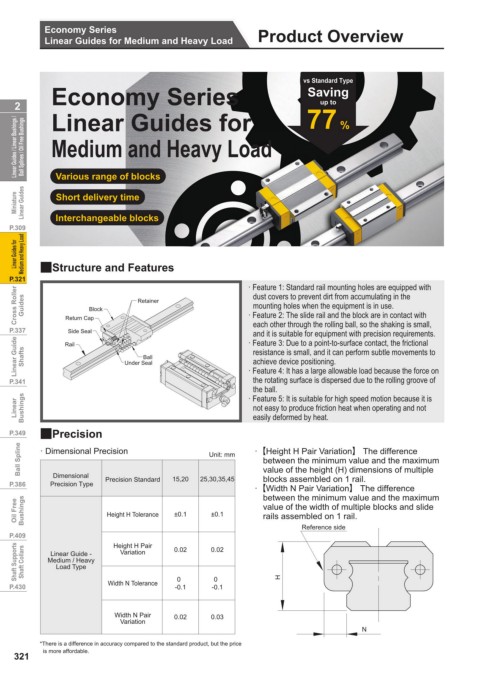

P.321 QStructure and Features · Feature 1: Standard rail mounting holes are equipped with · Basic Static Rated Load (Co) P.321

deformation amount of the rolling surface on the contact part bearing the maximum stress equal to 0.0001 times the diameter of the rolling element.

Cross Roller Guides Block Retainer · Feature 2: The slide rail and the block are in contact with · Static Allowable Torque (MA, MB, MC) Guides Cross Roller

dust covers to prevent dirt from accumulating in the

The static torque load limit under the action of torque load is determined by the basic static rated load Co and the same permanent deformation amount.

mounting holes when the equipment is in use.

Allowable Load (N)≤Co/fS

each other through the rolling ball, so the shaking is small,

P.337 Return Cap · Feature 3: Due to a point-to-surface contact, the frictional M A fS: Static Safety Factor Co: Basic Static Rated Load (N) P.337

Allowable Torque (N·m)≤(MA, MB, MC)/fS

and it is suitable for equipment with precision requirements.

Side Seal

Linear Guide Shafts Rail Under Seal resistance is small, and it can perform subtle movements to M C M A MA, MB, MC: Static allowable torque (N·m) M C Shafts Linear Guide

Ball

achieve device positioning.

M B

the rotating surface is dispersed due to the rolling groove of

P.341 · Feature 4: It has a large allowable load because the force on P.341

the ball. M B

· Feature 5: It is suitable for high speed motion because it is

Linear Bushings not easy to produce friction heat when operating and not Up and down swing direction Left and right swing direction Rolling direction Bushings Linear

easily deformed by heat.

The basic static rated load Co at rest or at low speed shall be

P.349 QPrecision · Static Safety Factor (fS) Table-2 Static Safety Factor (Lower limit of fS) Lower limit of fS P.349

Operating Condition

used after dividing by the static safety factor fs shown in Table-2

Ball Spline · Dimensional Precision Unit: mm ·【Height H Pair Variation】 The difference according to the operating condition. Under normal operating condition 1~2 Ball Spline

2~4

When smooth movement performance is required

between the minimum value and the maximum

3~5

In case of vibration and impact

value of the height (H) dimensions of multiple

Dimensional

P.386 Precision Type Precision Standard 15,20 25,30,35,45 blocks assembled on 1 rail. P.386

·【Width N Pair Variation】 The difference

between the minimum value and the maximum

Oil Free Bushings Height H Tolerance ±0.1 ±0.1 value of the width of multiple blocks and slide Bushings Oil Free

rails assembled on 1 rail.

Reference side

P.409 Height H Pair P.409

Shaft Supports Shaft Collars Medium / Heavy Variation 0.02 0.02 Shaft Collars Shaft Supports

Linear Guide -

Load Type

0

0

P.430 Width N Tolerance -0.1 -0.1 H P.430

Width N Pair 0.02 0.03

Variation

N

*There is a difference in accuracy compared to the standard product, but the price

321 is more affordable.

1BSU @&/ JOEC

1BSU @&/ JOEC