Page 47 - MISUMI Thailand Economy Series

P. 47

Format Series Price Ratio Shipping Search Drawing Product Material Table Techinfo Others BD M D GM Format Series Price Ratio Shipping Search Drawing Product Material Table Techinfo Others BD M D GM

Title

Pict

Pict

Title

KW

KW

Date

Name

Name

Date

AK AK

M M

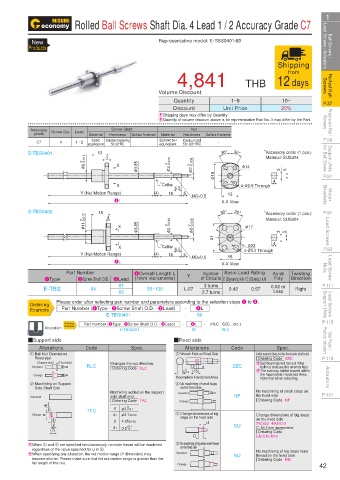

1 Economy series Runout Tolerance / Precautions Rolled Ball Screws Shaft Dia. 4 Lead 1 / 2 Accuracy Grade C7 1

Ball Screws

Ball Screws / Lead Screws / Actuators Products Representative model: E-TBS0401-80 Shipping Lead Screws / Actuators Ball Screws /

New

4,841

from

Rolled Ball Screws Volume Discount THB 12 days Screws Rolled Ball

1~9

10~

P.37 Quantity Unit Price 20% P.37

Discount

Precision Ball Screws Accuracy Screw Shaft E Shipping days may differ by Quantity. Screws Precision Ball

E Quantity of volume discount above is for representative Part No. It may differ by the Part.

Nut

Material

Material

Hardness

Hardness

P.59 grade Screw Dia. Lead equivalent Induction hardening Surface Treatment SCM415H Carburized Surface Treatment P.59

S55C

4

-

1 · 2

-

C7

equivalent

58~62HRC

58~62HRC

Support Units for Ball Screw E-TBS0401 0 φ 9 -0.014 13 3 X 0 -0.010 0 -0.008 30° 30° φ 14 * Accessory collar (1 pcs.) for Ball Screw Support Units

Material: SUS304

P.81 φ 3.85 φ 3 φ 2 φ 19 3 5 P.81

X * Collar 6.5 4- φ 2.9 Through 4

Motor Brackets Y (Nut Motion Range) (4) 18 5 M3×0.5 X-X View Brackets Motor

13

4L

P.91 E-TBS0402 0 -0.017 16 4 30° 30° * Accessory collar (1 pcs.) P.91

Material: SUS304

Lead Screws φ 11 X φ 3.85 0 φ 3 -0.010 0 -0.008 φ 2 21 φ 17 3 5 Lead Screws

φ 23

X

P.93 Y (Nut Motion Range) (4) * Collar 6.5 5 M3×0.5 15 4- φ 3.4 Through 4 P.93

18

Lead Screw Nuts QPrecautions Part Number 4L 4Overall Length L Y Number Basic Load Rating Axial Twisting Nuts Lead Screw

X-X View

Play

1Type

01

3 turns

P.111 (1) If the nut is removed from the screw shaft, the ball will fall off (6) In operation, if there is too much noise or sharp and harsh E-TBS 2Screw Shaft O.D. 3Lead (1mm increments) L-27 of Circuits C (Dynamic) kN C (Static) kN 0.02 or Direction P.111

0.42

0.57

55~130

Right

04

Less

2.7 turns

02

Lead Screws Support Units the nut and cannot be used. Do not disassemble, as this may sound, please make sure that the installation accuracy of Ordering Please order after selecting part number and parameters according to the selection steps 1 to 4. Support Units Lead Screws

the screw and the specifications of peripheral components

cause impurities to enter the interior and damage the

Part Number (1Type · 2Screw Shaft O.D. · 3Lead)

-

4L

assembly accuracy of each part. When the nut needs to be

such as motors and couplings are appropriate.

Example

E-TBS0401

removed, use a special auxiliary shaft.

P.115 (2) The outer circle, spiral groove and circulating parts of the (7) Although lithium soap-based grease has been applied at Alteration Ordering Part Number (1Type · 2Screw Shaft O.D. · 3Lead) - - - 4L 80 - - (RLC · SZC…etc.) P.115

the factory, it is required to apply new grease every 2~3

Example

screw shaft will be damaged by external force impact,

months as standard after receiving the goods.

E-TBS0401

RLC

80

Stop Plates / Position Indicators resulting in poor circulation and loss of function. Please take (8) Do not let the nut exceed the movement range of the ball QSupport side Code Spec. QFixed side Code Spec. Position Indicators Stop Plates /

screw nut, or screw out of the screw shaft, otherwise the

care to avoid it.

Alterations

Alterations

5

1

ball will fall off and the ball cycling parts will be damaged.

weight. Please be careful. Especially when it is used as a

Reversed

P.119 (3) Ball screws and nuts placed with an inclination may fall due to (9) Nut overstroke operation is prohibited. 1 Ball Nut Orientation 3 Wrench Flats on Fixed Side Adds wrench flats on the fixed side shaft end. P.119

Ordering Code SZC

vertical axis, the nuts are likely to fall due to weight. Please set (10) This product is a machined type, so there will be knife Standard (Fixed side) RLC Changes the nut direction. 2.5 4 SZC E Ball bearings will fall out if the

(Support side)

ball nut crosses the wrench flats

Actuators (4) Please check the flexibility by rotating the screw shaft with the scratches or color changes without affecting the use and Change Incomplete Hardened Area E The nut may not be moved within Actuators

patterns and color difference in its appearance. Small

up a fall prevention mechanism.

Ordering Code RLC

0

(15)

3-0.2

the Incomplete Hardened Area.

Note that when selecting.

fixed nut or rotating the nut with the fixed shaft.

main function are a normal phenomenon. Please feel free

Side Shaft End

on the fixed side

(5) Rotating the nut by hand may not feel smooth, but does not to use. 2 Machining on Support 4 No machining of small steps No machining of small steps on

P.131 affect the positioning precision. Please feel free to use. (11) The noise value of the screw after assembly is not Standard Machining added on the support Standard NF the fixed side P.131

side shaft end.

guaranteed. Ordering Code TFC Change Ordering Code NF

d1 d 0 L

TFC φ3-0.01

Change d d1 φ2.7±0.03 5 Change dimensions of big Change dimensions of big steps

steps on the fixed side

If the nut end face is moved out of L1 L 4.35±0.05 U on the fixed side

7≤C≤22 4≤U≤C-3

the range of right figure, it will L L1 0.5 0 CU C, U=1mm increments

+0.1

cause the ball to fall off, resulting (7) Ordering Code

Removal of nut No impact on Be careful of falling Checking for C CU-C15-U10

is prohibited the nut due to weight reverse action in malfunction.

E When 5 and 6 are specified simultaneously, no male thread will be machined 6 No machining of big steps male thread

regardless of the value specified for U in 5. on the fixed side No machining of big steps male

E When specifying any alteration, the nut motion range (Y dimension) may Standard NU thread on the fixed side

become shorter. Please make sure that the nut motion range is greater than the Ordering Code NU

full length of the nut. Change 42

110310689129

1BSU @&/ JOEC

1BSU @&/ JOEC