Page 105 - MISUMI Thailand Economy Series

P. 105

Format Series Price Ratio Shipping Search Drawing Product Material Table Techinfo Others BD M D GM Format Series Price Ratio Shipping Search Drawing Product Material Table Techinfo Others BD M D GM

Title

Pict

KW

Title

Pict

KW

Name

Date

Name

Date

AK AK

M M

1 1

Ball Screws / Lead Screws / Actuators Alteration Ordering Part Number (1Type · 2D) - - 3L - - F20 - - 5V - - 6S - - 7Q - 8C - 9J - - (AQ…etc.) Lead Screws / Actuators Ball Screws /

4F

Example

300

Q7

V7

S20

C-MTSRW10

AQ13.3

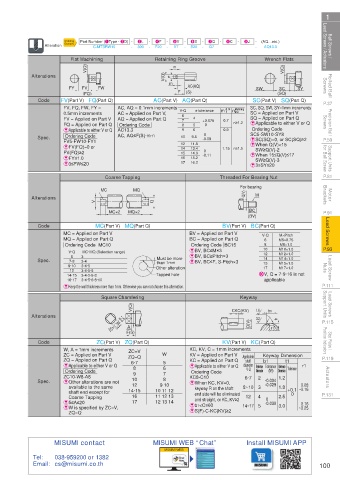

Flat Machining

Wrench Flats

Retaining Ring Groove

Rolled Ball Screws Alterations FY FV V(Q) FW V(Q) m e n F (S) SW (SQ) V(Q) SY Screws Rolled Ball

AC(AQ)

SC

(FQ)

SC(Part V) SQ(Part Q)

AC(Part V) AQ(Part Q)

P.37 Code FV(Part V) FQ(Part Q) AC, AQ = 0.1mm increments V·Q e tolerance m 0 +0.14 n limit SC, SQ, SW, SY=1mm increments P.37

FV, FQ, FW, FY =

Machining

Precision Ball Screws 0.5mm increments AC = Applied on Part V, 6 7 8 9 4 5 6 +0.075 0.7 n≥1.2 SQ = Applied on Part Q Screws Precision Ball

SC = Applied on Part V

FV = Applied on Part V

AQ = Applied on Part Q

E Applicable to either V or Q

Ordering Code

FQ = Applied on Part Q

0

Ordering Code

AC13.3

EApplicable to either V or Q

0.9

Ordering Code

9.6

ESC(SQ)=0, or SC(SQ)≥2

-0.09

P.59 Spec. FV5-FW10-FY1 AC, AQ≤F(S)-m-n 10 11.5 0 1.15 n≥1.5 SC5-SW10-SY8 P.59

E When Q(V)<15

12

Support Units for Ball Screw FV(FQ)≥2 15 14.3 0 E When 15≤Q(V)≤17 for Ball Screw Support Units

EFV(FQ)=0 or

13.4

14

SW≥Q(V)-2

-0.11

EFY≤1.0

15.2

16

SW≥Q(V)-3

17

16.2

E3≤FW≤20

E3≤SY≤20

P.81 Coarse Tapping Threaded For Bearing Nut P.81

Motor Brackets Alterations V MC MQ Q For bearing nut Brackets Motor

Q(V)

M

BC

P.91 MC×2 MQ×2 (BV) P.91

Lead Screws Code MC = Applied on Part V BV = Applied on Part V V·Q M6×0.75 Lead Screws

BV(Part V) BC(Part Q)

MC(Part V) MQ(Part Q)

M×Pitch

BC = Applied on Part Q

MQ = Applied on Part Q

6

Ordering Code BC15

M8×1.0

8

P.93 Ordering Code MC10 Must be more EBV, BC≤M×3 10 M10×1.0 P.93

MC·MQ (Selection range)

V·Q

M12×1.0

12

EBV, BC≥Pitch×3

Lead Screw Nuts Spec. 14·15 3·4 Other alteration EBV, BC≤F, S-Pitch×3 X V, Q = 7·9·16 is not Nuts Lead Screw

6

3

M14×1.0

14

7·8

than 1mm

15

M15×1.0

3·4·5

9·10

17

M17×1.0

12

3·4·5·6

Tapped hole

3·4·5·6·8

16·17

3·4·5·6·8·10

P.111 E Keep the wall thickness more than 1mm. Otherwise you can not choose this alternation. applicable P.111

Lead Screws Support Units Square Chamfering CKC(KV) 1.6 b1 Support Units Lead Screws

Keyway

V(Q)

-0.1

P.115 Alterations 3.2 #W -0.3 A Q(V) 3.2 r1 t1 P.115

F(S)

Stop Plates / Position Indicators Code ZC(Part V) ZQ(Part Q) KV(Part V) KC(Part Q) Position Indicators Stop Plates /

ZC=V

KV = Applied on Part V

ZC = Applied on Part V

Applicable

P.119 W, A = 1mm increments ZQ=Q W KC, KV, C = 1mm increments Keyway Dimension P.119

ZQ = Applied on Part Q

KC = Applied on Part Q

shaft

b1

t1

EApplicable to either V or Q 6·7 5 6 E Applicable to either V or Q diameter Reference Tolerance Reference Tolerance r1

8

V·Q

Actuators Spec. ZC10-W8-A8 10 7 8 KC8-C10 6·7 2 -0.004 1.2 Actuators

Dimension

(N9)

Dimension

Ordering Code

Ordering Code

9

E Other alterations are not

E When KC, KV=0,

-0.029

0.08

9 10

12

available to the same

shaft end except for 14·15 10 11 12 keyway R on the shaft 8~10 3 1.8 +0.1 ~0.16

P.131 16 11 12 13 end side will be eliminated 0 P.131

Coarse Tapping and straight, or KC, KV≥2 12 4 0 2.5

E5≤A≤20 17 12 13 14 -0.030 0.16

E W is specified by ZC=V, Eb1<C≤60 14~17 5 3.0 ~0.25

ZQ=Q ES(F)-C-KC(KV)≥2

MISUMI contact MISUMI WEB “Chat” Install MISUMI APP

MISUMI WEB

Tel: 038-959200 or 1382

Email: cs@misumi.co.th 100

110310434339

1BSU @&/ JOEC

1BSU @&/ JOEC