Page 100 - MISUMI Thailand Economy Series

P. 100

Format Series Price Ratio Shipping Search Drawing Product Material Table Title Techinfo Others BD M D GM Format Series Price Ratio Shipping Search Drawing Product Material Table Title Techinfo Others BD M D GM

KW

Pict

KW

Pict

Name

Date

Date

Name

AK AK

M M

1 Economy series Product Overview Product Specifications Economy series 1

Lead Screws

Lead Screws

Ball Screws / Lead Screws / Actuators QEasy Assembly Design QLead screw Specification Lead Screws / Actuators Ball Screws /

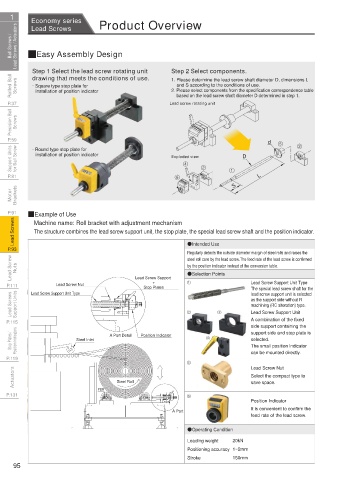

Rolled Ball Screws Step 1 Select the lead screw rotating unit Step 2 Select components. Type Straight Type Support Type Both Ends Stepped Type One End Stepped / One End Double Stepped Type Screws Rolled Ball

drawing that meets the conditions of use.

1. Please determine the lead screw shaft diameter D, dimensions L

and S according to the conditions of use.

· Square type stop plate for

2. Please select components from the specification correspondence table

installation of position indicator

based on the lead screw shaft diameter D determined in step 1.

P.37 Lead screw rotating unit Shape P.37

Precision Ball Screws Screws Precision Ball

P.59 · Round type stop plate for d 5 3 Unit: mm P.59

Support Units for Ball Screw installation of position indicator Exploded view D Shaft Pitch Effective Dia. diameter Lead Angle Screw shaft runout tolerance (max.) for Ball Screw Support Units

Screw shaft

Screw Shaft thread root Screw Shaft

Shaft Overall Length

Dia.

4

P.81 6 2 1 L 8 1.5 7.25 (MIN) 3°46' ~125 126~200 201~315 316~400 401~500 501~630 631~800 801~1000 1001~1200 P.81

-

0.14

(5.9)

0.27

-

-

0.21

0.1

0.35

S -

Motor Brackets 10 2 11 9 (7.2) 4°03' 0.09 0.12 0.16 0.21 0.27 0.35 0.46 0.58 Brackets Motor

12

(9.2)

3°19'

P.91 QExample of Use 14 3 12.5 (10.1) 4°22' 0.09 - P.91

Lead Screws The structure combines the lead screw support unit, the stop plate, the special lead screw shaft and the position indicator. 16 4 14.5 (12.1) 3°46' - 0.11 0.13 0.16 0.2 0.25 0.32 0.42 0.55 Lead Screws

Machine name: Roll bracket with adjustment mechanism

20

(15.1)

4°03'

18

P.93 IIntended Use 22 5 19.5 (16.1) 4°40' - 0.09 0.11 0.13 0.16 0.19 0.23 0.3 0.38 P.93

Regularly detects the outside diameter margin of steel rolls and raises the

Lead Screw Nuts steel roll core by the lead screw.The feed rate of the lead screw is confirmed 25 22.5 (19) 4°03' Nuts Lead Screw

by the position indicator instead of the conversion table.

ISelection Points

+

Lead Screw Nut

P.111 Lead Screw Support Unit Type Lead Screw Support 1 Lead Screw Support Unit Type QLead Screw Nut Specification P.111

Stop Plates

The special lead screw shaft for the

Lead Screws Support Units 2 3 as the support side without R Standard Type Part Number / Type Compact Type Square Type Support Units Lead Screws

lead screw support unit is selected

machining (RC alteration) type.

Lead Screw Support Unit

P.115 A combination of the fixed Round Flanged Cut Flange 2-hole Cut Flange 4-hole Square Flanged Round Flanged Cut Flange 2-hole Wide Block P.115

side support containing the

Stop Plates / Position Indicators Steel Inlet A Part Detail Position Indicator 4 selected. Nominal Pitch Position Indicators Stop Plates /

support side and stop plate is

Thread

Diameter

The small position indicator

P.119 can be mounted directly. P.119

5 Lead Screw Nut

Actuators Steel Roll Select the compact type to Allowable Dynamic Thrust (N) Actuators

save space.

PBR 8 1.5 1250 — — —

P.131 6 10 2 2168 — 1717 — 2168 P.131

Position Indicator 12 2 3332 2669 3332

It is convenient to confirm the

A Part 14 3 4165 3332 4165

feed rate of the lead screw.

16 3 5670 4539 5670

IOperating Condition 20 4 8339 6673 8339

22 5 10506 8407 10506

Loading weight 20kN

Positioning accuracy 1~2mm 25 5 12087 9673 12087

Stroke 150mm

95

1BSU @&/ JOEC

1BSU @&/ JOEC