Page 103 - MISUMI Thailand Economy Series

P. 103

Table

BD

GM

Series

Search

Shipping

Product

Techinfo

Format Series Price Ratio Shipping Search Drawing Product Material Table Title Techinfo Others BD M M D D GM Format Series Price Ratio Shipping Search Drawing Product Material Table Techinfo Others BD M D GM

Price Ratio

Material

Format

Drawing

Others

Title

Pict

Title

KW

Pict

KW

Date

Date

Name

Name

Pict

Name

KW

Date

AK AK

AK

M M M

1 Economy series Alteration Options Lead Screws-Straight 1

Lead Screws

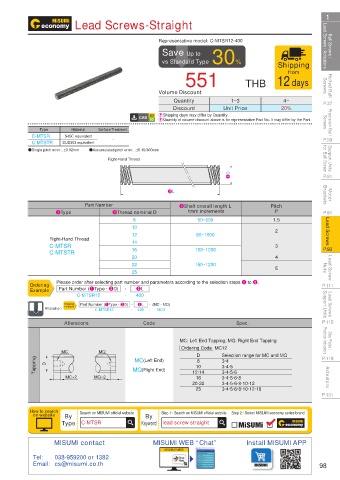

Ball Screws / Lead Screws / Actuators QAlteration Options Representative model: C-MTSR12-400 Shipping Lead Screws / Actuators Ball Screws /

Save Up to

30%

vs Standard Type

551

from

Rolled Ball Screws Flat Machining Threaded For Volume Discount THB 12 days Screws Rolled Ball

4~

1~3

P.37 Bearing Nut Quantity Unit Price 20% P.37

Discount

Precision Ball Screws Wrench Flats Type Material Surface Treatment E Shipping days may differ by Quantity. Screws Precision Ball

E Quantity of volume discount above is for representative Part No. It may differ by the Part.

S45C equivalent

P.59 C-MTSR SUS303 equivalent - P.59

C-MTSTR

Support Units for Ball Screw Retaining Chamfering ISingle pitch error…±0.02mm IAccumulated pitch error…±0.15/300mm for Ball Screw Support Units

Square

Right-Hand Thread

P.81 Ring Groove 2D P.81

Motor Brackets 3L Brackets Motor

Coarse Tapping Keyway Part Number 3Shaft overall length L Pitch

P

P.91 1Type 2Thread nominal D 1mm increments 1.5 P.91

50~500

8

Lead Screws Right-Hand Thread 10 80~1000 2 Lead Screws

12

P.93 Precautions for Selecting Alteration Machining conditions for combining C-MTSR 14 100~1200 3 4 P.93

16

C-MTSTR

"square chamfering" and "coarse tapping"

Lead Screw Nuts Reserve a gap of The interval The phase of each machining is Specifying alteration which Shaft end Square Coarse Tapping 22 150~1200 5 Nuts Lead Screw

20

Precaution4

Precaution1

Precaution2

Precaution3

Square Chamfering

random and may not be aligned in

overlaps another

between the

2mm or more from

25

machining is unavailable.

a row ,when multiple alterations

the stepped part to

alterations must be

Width

of the NG examples)

shows one of the examples)

P.111 specify the alteration more than 2mm are specified. (The following figure (The following figure shows one diameter Chamfering Tap Dia. Ordering Please order after selecting part number and parameters according to the selection steps 1 to 3. P.111

Part Number (1Type · 2D)

-

3L

Alteration A

Example

3

6~10

5~8

(Keyway)

Lead Screws Support Units Must be more than 2mm Must be more than 2mm Alteration A Phase Alteration B Rotation direction 11~14 8~10 3·4 Alteration Ordering C-MTSR12 - - 400 - (MC · MQ) Support Units Lead Screws

(Keyway)

(Wrench Flats)

Part Number (1Type · 2D) -

3L

Example

MC3

-

C-MTSR12

400

Alteration B

Rotation

Alteration

Alteration B

direction

(Flat Machining)

P.115 Stepped Part Alteration A As shown in the above figure, The overlap position 15~19 10~14 3·4·5 Alterations Code Spec. P.115

phases are random, so the

of alteration A, B

alteration A and B on the same

Stop Plates / Position Indicators (1) When specifying the alteration position, reserve a gap of 2mm or more from the stepped part (refer to the illustration of Precaution 1). MC: Left End Tapping; MQ: Right End Tapping Position Indicators Stop Plates /

3·4·5·6·8

14~20

20~25

axis may not be aligned in a row.

Ordering Code MC12

P.119 (2) When multiple alterations are selected, the machining parts need to be spaced by more than 2mm (refer to the illustration of Precaution 2). MC MQ D Selection range for MC and MQ P.119

8

(3) When combined with Flat Machining, Wrench Flat, Square Chamfering, and Keyway, each machining phase is random Tapping D MC(Left End) 10 3·4

3·4·5

Actuators (4) When 2 or more alterations are specified on the same shaft part, it may not possible to machine due to the correlation. MC×2 MQ×2 MQ(Right End) 12·14 3·4·5·6 Actuators

(refer to the illustration of Precaution 3).

3·4·5·6·8

16

20·22

(5) Specifying alteration which overlaps another machining is unavailable (refer to the illustration of Precaution 4).

25 3·4·5·6·8·10·12

3·4·5·6·8·10·12·16

P.131 P.131

QPrecautions for use

How to search Search on MISUMI official website Step 1 Search on MISUMI official website Step 2 Select MISUMI economy series brand

By

By

1. Do not drop or knock the lead screw. Otherwise it may cause scratches or damages. Attention should on website Type C-MTSR Keyword lead screw straight

be paid to the fact that impact can cause functional damage, even if it is not visible.

2. When contacting the product, please use protective gloves, safety shoes and other protective

equipment to ensure safety. MISUMI contact MISUMI WEB “Chat” Install MISUMI APP

MISUMI WEB

Tel: 038-959200 or 1382

Email: cs@misumi.co.th 98

1BSU @&/ JOEC

1BSU @&/ JOEC