Page 873 - MISUMI Thailand Economy Series

P. 873

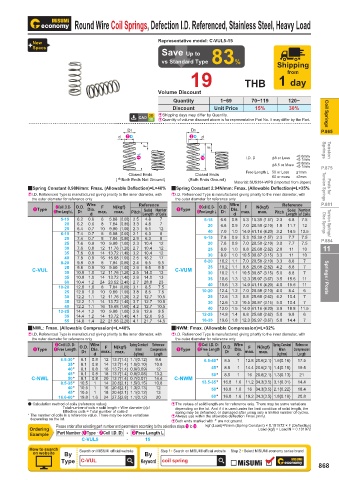

Round Wire Coil Springs, Defection I.D. Referenced, Stainless Steel, Heavy Load

New Representative model: C-VUL5-15

Specs

Save Up to

vs Standard Type 83% Shipping

19 THB 1 day

from

Volume Discount

Quantity 1~69 70~119 120~

Discount Unit Price 15% 30%

E Shipping days may differ by Quantity. Coil Springs

E Quantity of volume discount above is for representative Part No. It may differ by the Part.

D1 D1 D1 D1 P.865

d 2D d 2D 2D d 2D d

F F

F F Springs Tension

3L 3L 3L 3L I.D. D φ8 or Less +0.6mm

+0.1mm

φ8.5 or More +0.8mm P.875

+0.1mm

Closed Ends Closed Ends Free Length L 50 or Less ±1mm

Closed Ends

Closed Ends

±2mm

60 or more

(Both Ends Ground)

( * Both Ends Not Ground)

( * Both Ends Not Ground) (Both Ends Ground)

Material: SUS304-WPB (Imported from Japan)

QSpring Constant 0.98N/mm: Fmax. (Allowable Deflection)=L×40% QSpring Constant 2.94N/mm: Fmax. (Allowable Deflection)=L×35% Tension Springs Posts for

E I.D. Referenced Type is manufactured giving priority to the inner diameter, with E I.D. Referenced Type is manufactured giving priority to the inner diameter, with

the outer diameter for reference only the outer diameter for reference only

Wire F N{kgf} Reference 2Coil I.D. D- O.D. Wire F N{kgf} Reference P.881

2Coil I.D. D- O.D.

1Type Dia. Solid Number 1Type Dia. Solid Number

3Free Length L D1 d max. max. Pitch Length of Coils 3Free Length L D1 d max. max. Pitch Length of Coils

5-15 6.2 0.6 6 5.88 {0.60} 2.5 4.8 7 5-15 6.6 0.8 5.3 15.39 {1.57} 2.3 6.8 7.5

20 6.2 0.6 8 7.84 {0.80} 3.3 4.8 7 20 6.8 0.9 7.0 20.58 {2.10} 1.8 11.7 12 Disc Springs Torsion Springs/

25 6.4 0.7 10 9.80 {1.00} 2.3 9.1 12

6-15 7.4 0.7 6 5.88 {0.60} 2.1 6.3 8 40 7.0 1.0 14.0 41.16 {4.20} 3.2 14.5 13.5

20 7.4 0.7 8 7.84 {0.80} 2.9 6.3 8 6-15 7.8 0.9 5.3 15.39 {1.57} 2.3 7.7 7.5 P.884

25 7.6 0.8 10 9.80 {1.00} 2.3 10.4 12 20 7.8 0.9 7.0 20.58 {2.10} 3.0 7.7 7.5

30 7.6 0.8 12 11.76 {1.20} 2.7 10.4 12 25 8.0 1.0 8.8 25.68 {2.62} 2.8 11 10 11

35 7.6 0.8 14 13.72 {1.40} 3.2 10.4 12 30 8.0 1.0 10.5 30.87 {3.15} 3.3 11 10

40 7.8 0.9 16 15.68 {1.60} 2.5 16.2 17

8-20 9.8 0.9 8 7.84 {0.80} 2.4 9.5 9.5 8-20 10.2 1.1 7.0 20.58 {2.10} 3.3 8.8 7

9.5

9.8

0.9

C-VUL 25 10.0 1.0 10 9.80 {1.00} 2.9 14.0 9.5 C-VUM 25 10.2 1.1 8.8 25.68 {2.62} 4.2 8.8 7 7

12 11.76 {1.20} 2.5

13

30

8.8

30

10.2 1.1 10.5 30.87 {3.15} 5.0

35 10.0 1.0 14 13.72 {1.40} 2.9 14.0 13 35 10.6 1.3 12.3 35.97 {3.67} 3.5 15.6 11 Springs / Posts

60 10.4 1.2 24 23.52 {2.40} 2.7 28.8 23

10-20 12.0 1.0 8 7.84 {0.80} 3.1 8.5 7.5 40 10.6 1.3 14.0 41.16 {4.20} 4.0 15.6 11

25 12.0 1.0 10 9.80 {1.00} 3.8 8.5 7.5 10-20 12.4 1.2 7.0 20.58 {2.10} 4.0 8.4 6

30 12.2 1.1 12 11.76 {1.20} 3.2 12.7 10.5 25 12.6 1.3 8.8 25.68 {2.62} 4.2 10.4 7

35 12.2 1.1 14 13.72 {1.40} 3.7 12.7 10.5 30 12.6 1.3 10.5 30.87 {3.15} 5.0 10.4 7

40 12.2 1.1 16 15.68 {1.60} 4.2 12.7 10.5 40 13.0 1.5 14.0 41.16 {4.20} 3.8 18.8 11.5

12-25 14.4 1.2 10 9.80 {1.00} 2.9 12.6 9.5

35 14.4 1.2 14 13.72 {1.40} 4.1 12.6 9.5 12-25 14.8 1.4 8.8 25.68 {2.62} 5.0 9.8 6

55 14.8 1.4 22 21.56 {2.20} 4.1 21.7 14.5 16-35 19.6 1.8 12.3 35.97 {3.67} 5.8 14.4 7

QNWL: Fmax. (Allowable Compression)=L×40% QNWM: Fmax. (Allowable Compression)=L×32%

E I.D. Referenced Type is manufactured giving priority to the inner diameter, with E I.D. Referenced Type is manufactured giving priority to the inner diameter, with

the outer diameter for reference only the outer diameter for reference only

2Coil I.D. D- Wire Spring Constant Reference 2Coil I.D. D- Wire Spring Constant Reference

1Type 3Free Length O.D. Dia. F N{kgf} N/mm Compression 1Type 3Free Length O.D. Dia. F N{kgf} N/mm Compression

L D1 d max. max. {kgf/mm} Length L D1 d max. max. {kgf/mm} Length

6.5-30 * 8.1 0.8 12 13.7{1.4} 1.1{0.12} 9.6 6.5-40 * 8.5 1 12.8 20.6{2.1} 1.6{0.16} 17.5

35 * 8.1 0.8 14 13.7{1.4} 1.0{0.10} 10.8

40 * 8.1 0.8 16 13.7{1.4} 0.9{0.09} 12 45 * 8.5 1 14.4 20.6{2.1} 1.4{0.15} 19.5

45 * 8.1 0.8 18 13.7{1.4} 0.8{0.08} 13.2 50 * 8.5 1 16 20.6{2.1} 1.3{0.13} 21

C-NWL 50 * 8.1 0.8 20 13.7{1.4} 0.7{0.07} 14.4 C-NWM

8.5-35 * 10.5 1 14 20.6{2.1} 1.5{0.15} 10.8 13.5-35 * 16.8 1.6 11.2 34.3{3.5} 3.1{0.31} 14.4

40 * 10.5 1 16 20.6{2.1} 1.3{0.13} 12 50 * 16.8 1.6 16 34.3{3.5} 2.1{0.22} 18.4

45 * 10.5 1 18 20.6{2.1} 1.1{0.12} 13

16.6-60 * 19.8 1.6 24 27.5{2.8} 1.1{0.12} 20 60 * 16.8 1.6 19.2 34.3{3.5} 1.8{0.18} 20.8

I Calculation method of coils (reference value): E The values of solid length are for reference only. There may be some variations

Total number of coils = solid length ÷ Wire diameter (d)-1 depending on the lot. And if it is used under the limit condition of solid length, the

Effective coils = Total number of coils-2 spring may be deformed, or damaged after using only a limited number of cycles.

* The number of coils is a reference value. There may be some variations E Always use within the allowable deflection Fmax.(mm).

depending on the lot. E Both ends marked with * are not ground.

Please order after selecting part number and parameters according to the selection steps 1 to 3. kgf (Load)=N/mm (Spring Constant) × 0.101972 × F (Deflection)

Ordering Load {kgf} = Load N × 0.101972

Example Part Number (1Type · 2Coil I.D. D) - 3Free Length L

C-VUL5 - 15

How to search Search on MISUMI official website Step 1 Search on MISUMI official website Step 2 Select MISUMI economy series brand

on website By By

Type C-VUL Keyword coil spring

868