Page 874 - MISUMI Thailand Economy Series

P. 874

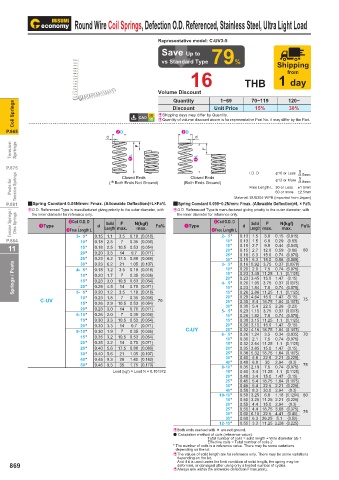

Round Wire Coil Springs, Defection O.D. Referenced, Stainless Steel, Ultra Light Load

Representative model: C-UV3-5

Save Up to

vs Standard Type 79% Shipping

16 THB 1 day

from

Volume Discount

Quantity 1~69 70~119 120~

Coil Springs E Shipping days may differ by Quantity. 15% 30%

Unit Price

Discount

E Quantity of volume discount above is for representative Part No. It may differ by the Part.

P.865 2D 2D

d d

Tension Springs 3L F 3L F

P.875 I.D. D φ10 or Less 0

-0.5mm

Closed Ends

Closed Ends

0

Posts for Tension Springs ( * Both Ends Not Ground) (Both Ends Ground) Free Length L 50 or Less ±1.5mm

φ12 or More

-0.8mm

60 or more ±2.5mm

Material: SUS304-WPB (Imported from Japan)

P.881 QSpring Constant 0.05N/mm: Fmax. (Allowable Deflection)=L×Fa% QSpring Constant 0.098~0.2N/mm: Fmax. (Allowable Deflection)=L × Fa%

E O.D. Referenced Type is manufactured giving priority to the outer diameter, with

E O.D. Referenced Type is manufactured giving priority to the outer diameter, with

Torsion Springs / Disc Springs the inner diameter for reference only. d Length max. N{kgf} Fa% the inner diameter for reference only. d Length max. N{kgf} Fa%

2Coil O.D. D

2Coil O.D. D

Solid

F

Solid

F

1Type

1Type

-

-

max.

max.

3Free Length L

3Free Length L

P.884 3- 5 * * 0.15 1.1 3.5 0.18 {0.018} 2- 5 * * 0.13 1.5 3.0 0.15 {0.015}

6.0

0.13 1.5

0.29 {0.03}

10

10

0.35 {0.036}

7

0.18 2.5

9.0

0.44 {0.045}

11 15 * 0.18 2.5 10.5 0.53 {0.054} 15 * * 0.15 2.7 12.0 0.59 {0.06} 60

0.15 2.7

20

20 * 0.20 3.3 14 0.7 {0.071} 25 * 0.18 6.3 15.0 0.74 {0.076}

25 * * 0.23 6.2 17.5 0.88 {0.089} 3- 5 * * 0.18 6.3 18.0 0.88 {0.089}

30

Springs / Posts 4- 5 * * * * 0.18 1.2 10.5 0.53 {0.054} 4- 5 * * * * * 0.20 2.0 7.5 0.74 {0.075}

1.05 {0.107}

21

30

0.23 6.2

0.16 0.92 3.75 0.37 {0.0378}

10

3.5

0.18 {0.018}

15

0.23 3.45 11.25 1.1 {0.1125}

0.20 1.7

0.35 {0.036}

7

10

20

0.23 3.45 15.0 1.47 {0.15}

0.23 3.0

15

0.20 1.05 3.75 0.37 {0.0375}

14

0.70 {0.071}

20

0.29 4.5

0.23 1.84

10

7.5

0.74 {0.075}

0.29 4.64 15.0 1.47 {0.15}

20

10

7

0.35 {0.036}

0.23 1.8

C-UV 5- 5 * * 0.20 1.2 3.5 1.18 {0.018} 70 15 * * * 0.26 2.86 11.25 1.1 {0.1125} 75

0.30 5.4 18.75 1.84 {0.1875}

25

15 * 0.26 2.9 10.5 0.53 {0.054} 30 * 0.30 5.4 22.5 2.26 {0.23}

20 * 0.23 3.0 14 0.70 {0.071} 5- 5 * 0.23 1.15 3.75 0.37 {0.0378}

6-10 * 0.26 2.0 7 0.35 {0.036} 10 * 0.26 1.82 7.5 0.74 {0.075}

15 * 0.30 3.3 10.5 0.53 {0.054} 15 * 0.30 3.15 11.25 1.1 {0.1125}

20 * 0.30 3.3 14 0.7 {0.071} 20 * 0.30 3.15 15.0 1.47 {0.15}

8-10 * 0.30 1.9 7 0.35 {0.036} C-UY 25 * * 0.32 4.16 18.75 1.84 {0.1875} 70

3.5

0.34 {0.035}

0.26 1.24

15 * 0.35 3.2 10.5 0.53 {0.054} 6- 5 * 0.30 2.1 7.5 0.74 {0.075}

10

20 * 0.35 3.2 14 0.70 {0.071} 15 * 0.32 2.64 11.25 1.1 {0.1125}

25 * 0.40 5.6 17.5 0.88 {0.089} 20 * 0.35 3.85 15.0 1.47 {0.15}

30 * 0.40 5.6 21 1.05 {0.107} 25 * 0.38 5.32 18.75 1.84 {0.1875}

40 * 0.45 9.3 28 1.40 {0.143} 30 * * 0.40 6.8 22.5 2.21 {0.225}

30

0.40 6.8

2.94

40

{0.3}

50 * 0.45 9.3 35 1.75 {0.179} 8-10 * 0.35 2.19 7.5 0.74 {0.075} 75

Load (kgf) = Load N × 0.101972 15 * 0.40 3.4 11.25 1.1 {0.1125}

20 * 0.40 3.4 15.0 1.47 {0.15}

25 * 0.45 5.4 18.75 1.84 {0.1875}

30 * 0.45 5.4 22.5 2.21 {0.225}

40 * 0.50 8.3 30.0 2.94 {0.3}

10-10 * 0.50 3.25 6.0 1.18 {0.1204} 60

15 * 0.50 3.25 11.25 2.21 {0.225}

20 * 0.55 4.4 15.0 2.94 {0.3}

25 * 0.55 4.4 18.75 3.68 {0.375}

30 * 0.60 6.15 22.5 4.41 {0.45} 75

35 * 0.60 6.3 26.25 5.1 {0.52}

12-15 * 0.55 3.3 11.25 2.206 {0.225}

E Both ends marked with * are not ground.

I Calculation method of coils (reference value):

Total number of coils = solid length ÷ Wire diameter (d)-1

Effective coils = Total number of coils-2

* The number of coils is a reference value. There may be some variations

depending on the lot.

E The values of solid length are for reference only. There may be some variations

depending on the lot.

And if it is used under the limit condition of solid length, the spring may be

869 deformed, or damaged after using only a limited number of cycles.

E Always use within the allowable deflection Fmax.(mm).