Page 1599 - MISUMI Thailand Economy Series

P. 1599

[Technical Data]

Selection of Ball Screws 3

6. Life Span 7. Screw Shaft Mounting Arrangements 9. Rigidity

Ball screw's life is defined as: Total number of rotations, time, or distance where either the ball rolling surfaces or the balls begin to exhibit Representative ball screw mounting arrangements are shown below. To improve positioning accuracy and control response of a machine,

repetitive stress caused flaking. Ball screw's life can be calculated based on Basic Dynamic Load Rating with the following formula. considerations must be given to the rigidity of feed screw elements.

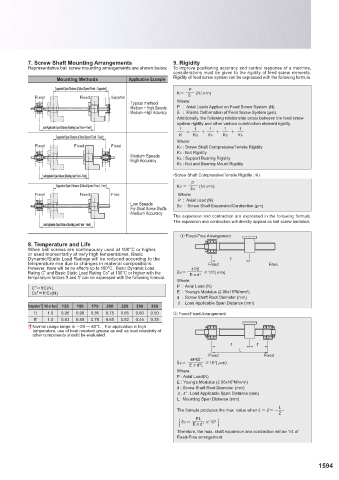

Mounting Methods Application Example Rigidity of feed screw system can be expressed with the following formula.

Life Calculation Example

Supported Span Distance (Critical Speed: Fixed – Supported ) P

<Requirements> K= (N/Om)

· Ball Screw Model BSS1520(Ø15 Lead 5(Thread Pitch 20)) Fixed Fixed Supported δ

· Mean Axial Load Pm 250N · Typical method Where:

· Mean Rotational Speed Nm 2118(min -1 ) · Medium ~ High Speeds P : Axial Loads Applied on Feed Screw System (N)

· Work Factor fw 1.2 · Medium ~High Accuracy δ : Elastic Deformation of Feed Screw System (µm)

Additionally, the following relationship exists between the feed screw

<Calculations> system rigidity and other various construction element rigidity.

Since Basic Dynamic Load Rating C for BSS1520 is 4400N, Load Applicable Span Distance (Buckling Load: Fixed – Fixed) 1 1 1 1 1

10 6 4400 3 K = KR + Kn + Kb + Kh

Lh= ) =24824(hr) Supported Span Distance (Critical Speed: Fixed – Fixed)

60×2118 ( 250×1.2 Where:

Fixed Fixed Fixed

Therefore, Life will be 24824 hours. KR : Screw Shaft Compressive/Tensile Rigidity

· Medium Speeds Kn : Nut Rigidity

· High Accuracy Kb : Support Bearing Rigidity

Kh : Nut and Bearing Mount Rigidity

Load Applicable Span Distance (Buckling Load: Fixed – Fixed) •Screw Shaft Compressive/Tensile Rigidity : KR

P

Supported Span Distance (Critical Speed: Fixed – Free) KR= (N/Om)

δℓ

Fixed Fixed Free Where:

P : Axial Load (N)

· Low Speeds δR : Screw Shaft Expansion/Contraction (µm)

· For Short Screw Shafts

· Medium Accuracy

The expansion and contraction are expressed in the following formula.

The expansion and contraction will directly appear as ball screw backlash.

Load Applicable Span Distance (Buckling Load: Fixed – Fixed)

① Fixed-Free Arrangement

8. Temperature and Life

When ball screws are continuously used at 100°C or higher,

or used momentarily at very high temperatures, Basic

Dynamic/Static Load Ratings will be reduced according to the ℓ

temperature rise due to changes in material compositions. Fixed Free

However, there will be no effects up to 100°C. Basic Dynamic Load 4Pℓ

3

Rating C" and Basic Static Load Rating Co" at 100°C or higher with the δR= ×10 (Om)

2

EQd

temperature factors ft and ft' can be expressed with the following formula.

Where:

C"=ftC(N) P : Axial Load (N)

5

C0"=ft'C0(N) E : Young's Modulus (2.06x10 N/mm ) 2

d : Screw Shaft Root Diameter (mm)

R : Load Applicable Span Distance (mm)

Temperature °C 100 or less 125 150 175 200 225 250 350

ft 1.0 0.95 0.90 0.85 0.75 0.65 0.60 0.50 ② Fixed-Fixed Arrangement ℓ

ft' 1.0 0.93 0.85 0.78 0.65 0.52 0.46 0.35 L

E Normal usage range is -20 ~ 80℃ . For application in high Fixed Fixed

temperature, use of heat resistant grease as well as heat resistivity of

other components should be evaluated.

ℓ ℓ’

L

Average Axial Load and Average Rotational Seed Calculation Example 4Pℓℓ' Fixed Fixed

3

<Requirements> δR= ×10 (Om)

EQd L

2

Where:

P : Axial Load(N)

5

E : Young's Modulus (2.06x10 N/mm ) 2

d : Screw Shaft Root Diameter (mm)

R,R ' : Load Applicable Span Distance (mm)

L : Mounting Span Distance (mm)

<Calculations>

① Average Axial Load L

The formula produces the max. value whenR=R '=

2

343 3 M1500M0.294+10 3 M3000M0.412+324 3 M1500M0.294

PL

Pm = = 250(N) ( )

3

1500M0.294+3000M0.412+1500M0.294 δR= ×10

2

EQd

Therefore, the Average Axial Load Pm will be 250N. Therefore, the max. shaft expansion and contraction will be 1/4 of

② Average Rotational Speed Fixed-Free arrangement.

1500M0.294+3000M0.412+1500M0.294

Nm = = 2118(min -1 )

0.294+0.412+0.294

Therefore, the Average Rotational Speed Nm will be 2118rpm.

1593 1594

KJTIV JOEC

KJTIV JOEC